In order to compare the power generation performance of bifacial PERC and monofacial modules installed using different methods, LONGi and the CGC conducted a one-year pilot project test in Togtoh county between December 2019 and December 2020. The results showed that, under conditions of saline soil and high temperature irradiation, the first-year power degradation of both modules was less than 2.0%. Compared with their monofacial equivalents, however, the bifacial modules produced a 10.0% higher level of power generation. The modules were able to deliver a significant energy yield gain when installed with a single-axis tracker (SAT).

The five resulting conclusions are as set out below:

1. Bifacial modules can deliver significantly higher energy yield gains, on both fixed bracket and tracker

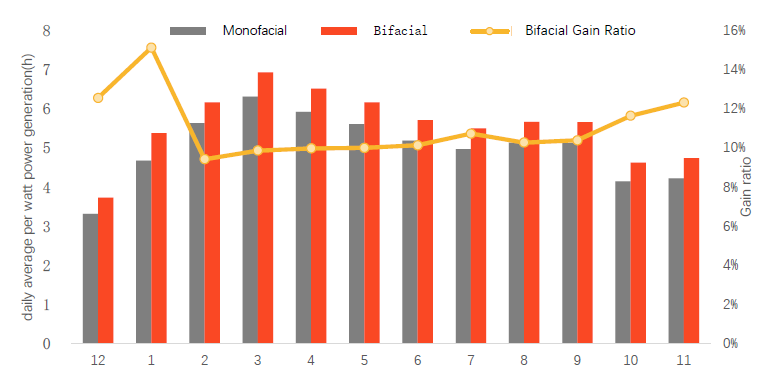

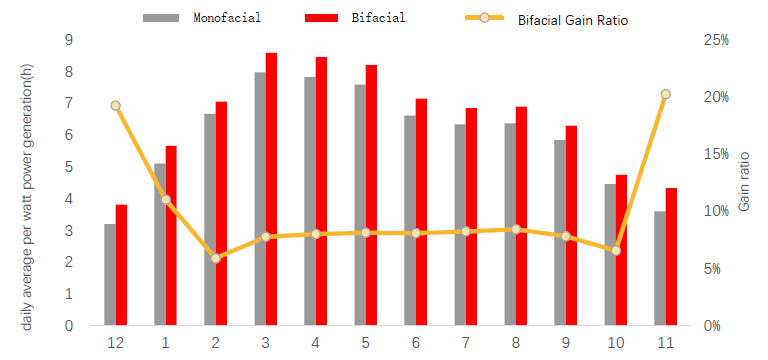

In this pilot project, both monofacial and bifacial modules were installed with fixed bracket (angle of inclination 32°) or SAT with inclination (angle 20°). The bifacial modules produced ~11.01% higher energy yield on the fixed bracket and ~9.91% higher energy yield on the SAT with inclination. The baseline of the energy yield when installed with a tracker system is higher, meaning that the energy yield gain of bifacial modules on a tracker system is slightly lower than when on a fixed bracket system.

Graph 1. two types of module power generation comparison with fixed bracket

Graph 2. two types of module power generation comparison

SAT with inclination

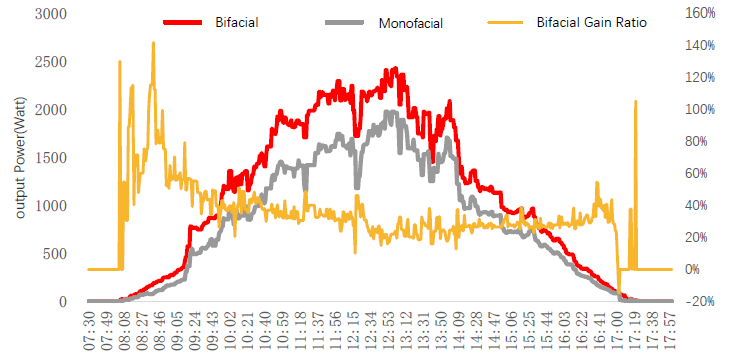

2. Energy yield gain of the bifacial module was over 20% in snowy season

The above annual gain curve shows that LONGi’s bifacial PERC module can deliver a higher energy yield gain in winter. On further investigation, there was snow and land covered with snow between Dec. 2019 and Jan. 2020 in this region, indicating that the energy yield gain was due to the high reflectivity of the snow. The energy yield gain was above 20%, as illustrated in the graph below, including curves for one-day of power output and for the power gain of monofacial and bifacial modules with fixed bracket after the snow.

Graph 3. two types of module power generation comparison

SAT with inclination angel 20° after snow

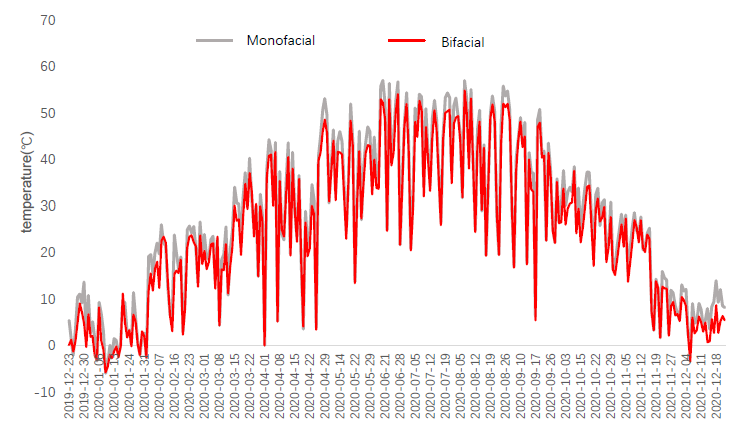

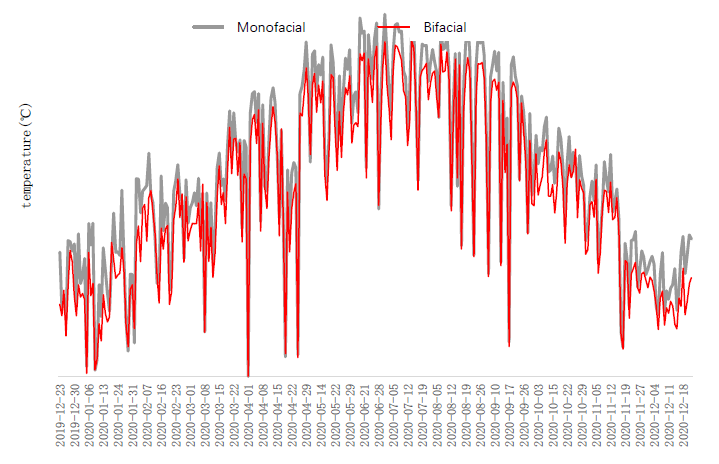

3. Working temperature of a bifacial module is lower than that of a monofacial equivalent

Bifacial modules were found to have a lower working temperature, largely due to their better thermal diffusivity and infrared transmittance when encapsulated with two pieces of 2 mm thick AR coating glass. With a lower working temperature, on the one hand, a module can increase power generation whereas, on the other, the ageing behaviour of encapsulated materials can be slowed down. The graph below shows different working temperatures for monofacial and bifacial modules installed on a SAT with inclination system.

Graph 4. Daily module average working temperature comparison with SAT with inclination

Graph 5. Daily modules max working temperature comparison with SAT with inclination

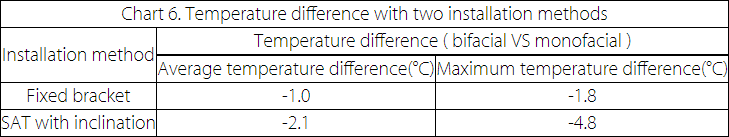

Chart 6. Temperature difference with two installation methods

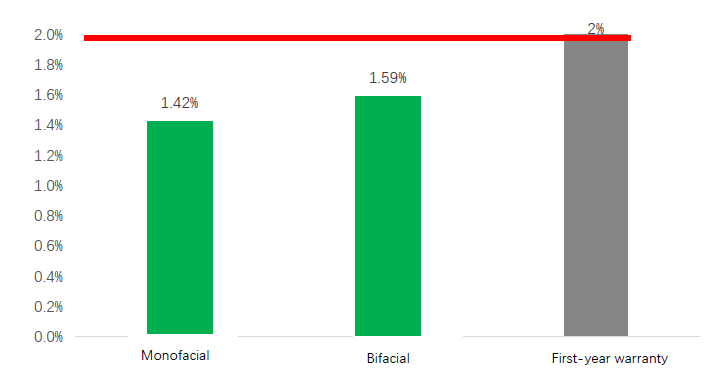

4. LONGi PERC module first-year power degradation <2%

There are high reliability requirements for PV modules because of challenging local environments, such as extremes of temperature, high irradiation, saline soil and sand erosion. Average power output degradation of LONGi monofacial and bifacial modules is 1.42% and 1.59% respectively, lower than the first-year power degradation warranty of 2.0% for the modules installed in the pilot project for the period from Nov. 2019 to Jun. 2021. Under the conditions set out above, there were no obvious differences beween the two types of module in terms of first-year power degradation.

Graph 7. two kinds of modules power degradation comparison

5. The power generation gain of a mono-PERC module is up to 5.0% compared with a Poly-PERC equivalent.

In the pilot project some Poly PERC modules were also installed with fixed bracket, with an annual power generation gain of up to 5.0%. The advantage of a Mono module is a lower tempertature coefficient, working temperature and low light response performance. The power degradation of the Poly product was shown to be more than 5.0%, due to a worse LID performance.

The principle of LONGi’s product and technology development is to focus on LCOE reduction and product reliability. The company always looks to achieve a balance of multiple factors, such as higher conversion efficiency and power generation. This explains why the Hi-MO series performs at a consistently high level in various third-party tests, subsequently delivering more product value for customers via excellent power generation capacity and reliability throughout its lifecycle.

*PV Pilot Plant located in Wushenjia Town, Togtoh County, Huhhot city, Inner Mongolia autonomous region (northern latitude 40°24′, east longitude 111°18′); mean altitude over 1000 meters, total horizontal irradiation 1650Kwh/m2, annual sunshine 3520 hours; with semiarid continental monsoon climate, annual average temperature 7.3℃. installation methods including horizontal single-axis tracker, single-axis tracker with inclination and fixed bracket under saline soil.

About LONGi

LONGi (SSE: 601012), headquartered in Xi'an, Shaanxi (China), is a global green energy technology company providing innovative solutions for customers in industrial, commercial and residential markets. Our solar solutions business help customers maximize the reliable landing of terminal value through LONGi PV industry chain, LONGi Lifecycle Quality. Our Hydrogen business helps ensure human comfort and health, advance energy efficiency and create sustainable zero-carbon infrastructure. LONGi became the first Chinese solar energy company to join the RE100, EV100, EP100 and SBTi initiatives, set up to promote zero-carbon solar and sustainable development. For more information visit www.Longi.com.