In order to verify the energy gains of bifacial PERC modules in different environments, LONGi cooperated with top third-party authorities to build many pilot projects in 2018. Among them, the TüV Rheinland pilot project in India mainly researched the difference of bifacial PERC modules, multi-crystalline black silicon modules, monofacial PERC modules and N-type bifacial modules under white gravel surface conditions. This pilot project has accumulated more than 6 months of data since September 2018. The whitepaper will conduct specific analysis based on the semi-annual report of TüV Rheinland pilot project in India and power generation data.

1)Project information

Located in Chennai, east coast of India with tropical wet and dry climate, specific information of the pilot project is shown in the below picture.

Figure 1.The location information of pilot project in India

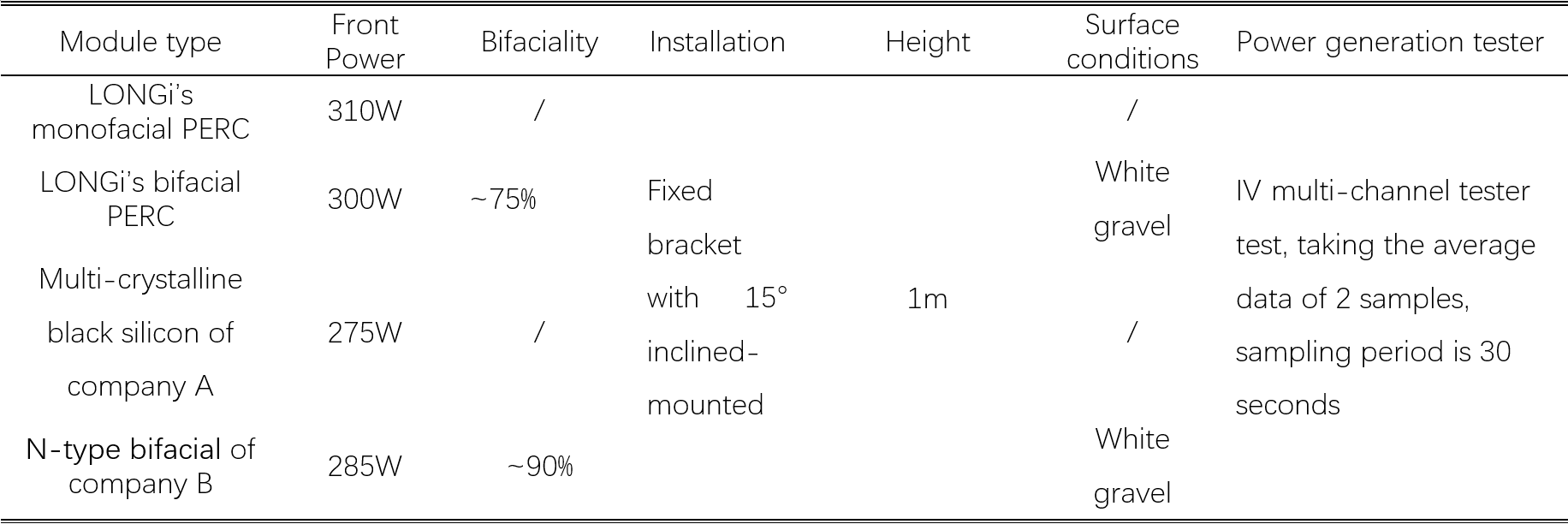

This pilot project used 2 modules for each type and installed in the same row with a total of 8 modules. The 4 types of modules are: LONGi’s monofacial PERC module, LONGi’s bifacial PERC module (with frame), multi-crystalline black silicon module of company A, N-type bifacial module of company B (without frame). All the modules are fixed bracket with 15° inclined-mounted and 1m high above the ground. All the 4 bifacial modules are paved with white gravel, as shown in the figure below:

Figure 2. Field photos of pilot project in India

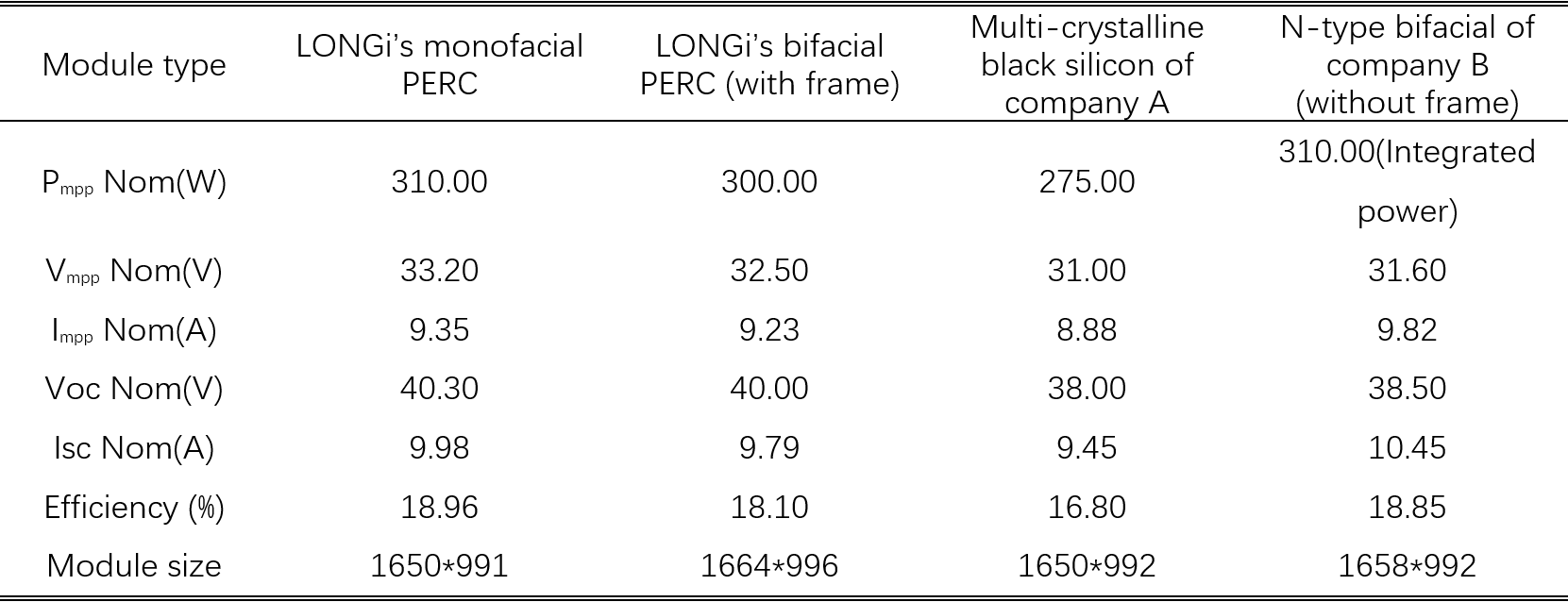

Table 1. Electrical characteristics and dimension of the test sample

Table 2. Design scheme of pilot project in India

All modules used in the pilot project in India have passed the tests of appearance, EL, and electrical performance. The power generation data of each module is read by the IV multi-channel tester. The front test power of the module is used to calculate the per watt power generation. The average power generation of the 2 modules is used to analyze the power generation capability of a certain module (Under the premise of that the electricity generated of the two modules is equivalent). The bracket is equipped with an pyranometer to test in-plane global irradiance, horizontal, diffuse and rear irradiance (GPoA, GHor Gd, Grear), and three pyranometers are installed on the back of the module to test the irradiance in different heights (1 m, 1.2 m, 1.4 m). The sampling period of the IV multi-channel tester and the pyranometers is 30 seconds.

2)Power generation performance of four type modules

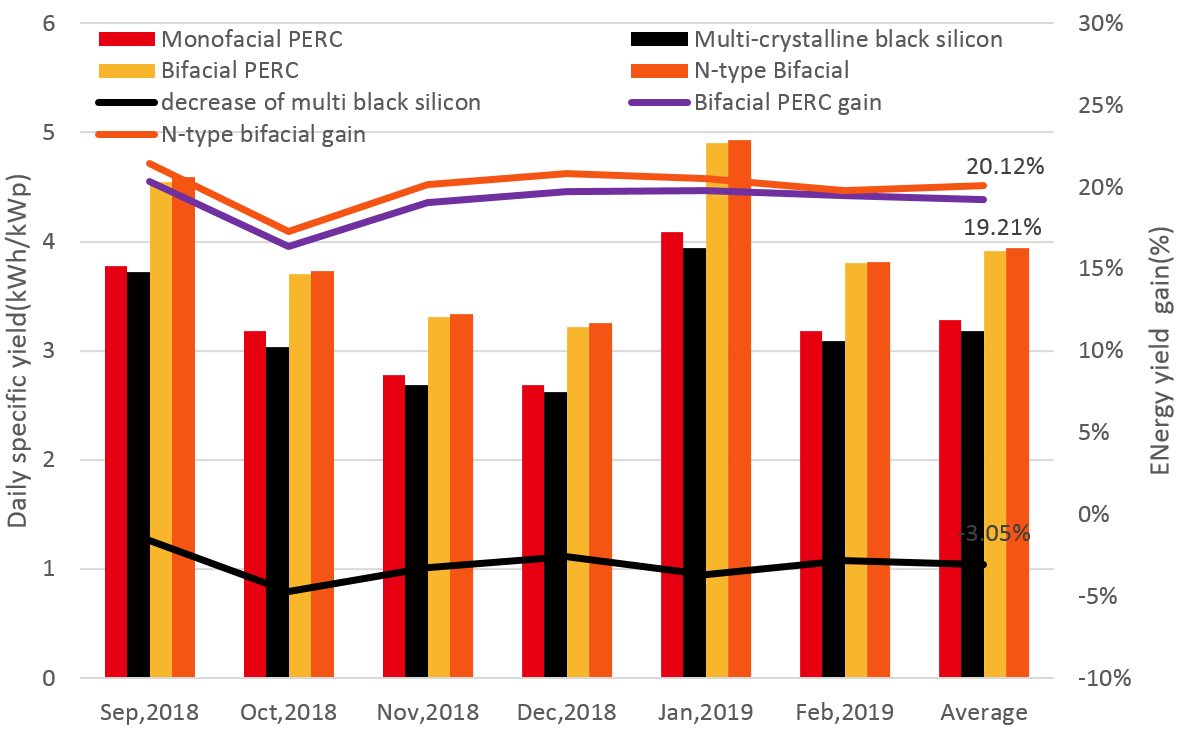

The power generation of the four type modules from September 2018 to February 2019 is shown in Figure 3: Compared with PERC monofacial modules, the power generation gains of the PERC bifacial modules and N-type bifacial modules are respectively 19.21% and 20.12% due to the increased rear-side power generation, the N-type bifacial modules are slightly higher than P-type bifacial modules by 0.76%, and the difference is mainly caused by the edge of the frame through analysis (The theoretical calculation of the framed module will be about 1% less due to the partial shaded compared with the frameless module), if the effect of the frame is removed, the power generation capacity of the two is basically the same (the bifacial module with frame has obvious advantages in long-term reliability, analysis article will be followed); the multi-crystalline black silicon module generates 3.05% less power than the monofacial PERC module, which is derived from the superior power temperature coefficient and low irradiance performance of the monocrystalline PERC module. Correspondingly, the power generation gain of the PERC and N-type bifacial relative to the multi-crystalline modules reaches 22.96% and 23.90%. According to the test of TÜV Rhein, the power temperature coefficients of the LONGi PERC monofacial and bifacial modules are -0.347%/C and -0.363/C, and the multi-crystalline black silicon modules are 0.400%/C. According to the monthly data, the power generation gain is generally stable. Due to the power breakage in October 2018, the power generation gain is lower than the normal value.

Figure 3. Monthly power generation of four modules of pilot project in India

3) Correlation of power generation gain, rear side irradiation and scattering ratio

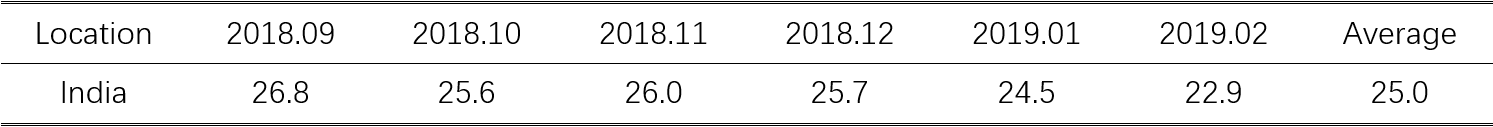

Table 3 shows the ratio of the average irradiation received on the rear side of the bifacial modules to the frontal irradiation in each month. The average irradiance on the backside of the 6-month Indian project is 25% of the frontal radiation. With the irradiance gain, multiplying the bifacial rate to estimate the power generation gain of the PERC bifacial module is 25%*75% = 18.75%, which is close to the measured value of 19.21%. There is a certain difference in the irradiation of the three positions on the rear side. The irradiation at 1.4m is slightly lower than the theoretical trend. Due to the area where the white gravel is laid to the north is insufficient, otherwise the radiation value and power generation gain on the rear side will be higher.

Table 3. The ratio of the rear side of the pilot project in India to the front irradiation [%]

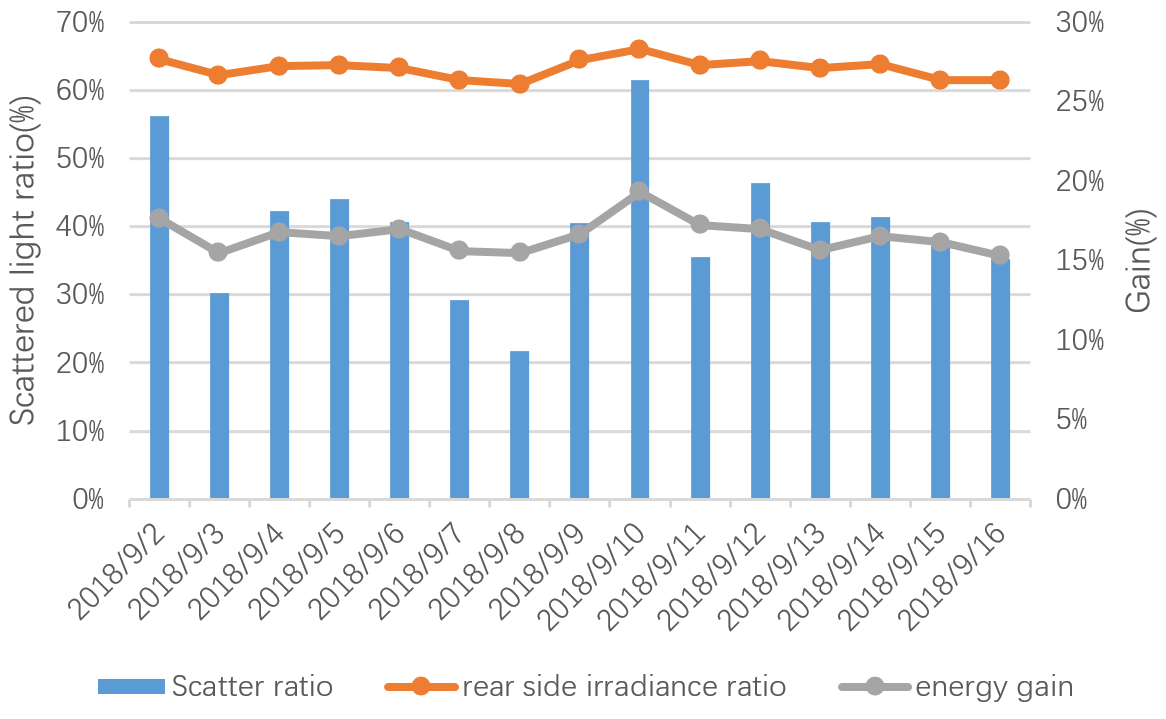

Figure 4 shows the correlation of the power generation gain of the PERC bifacial module, rear side radiation gain and scattering ratio for a period of time. It can be seen that the power generation gain is significantly correlated with the data of backside radiation gain and the scattering ratio. The higher ratio of solar radiation scattering, the higher ratio of the backside irradiation to the frontal irradiation of the module, and the higher power generation gain of the bifacial module.

Figure 4. Solar scattering ratio, backside radiation and power generation gain of PERC bifacial modules from September 2 to 16, 2018

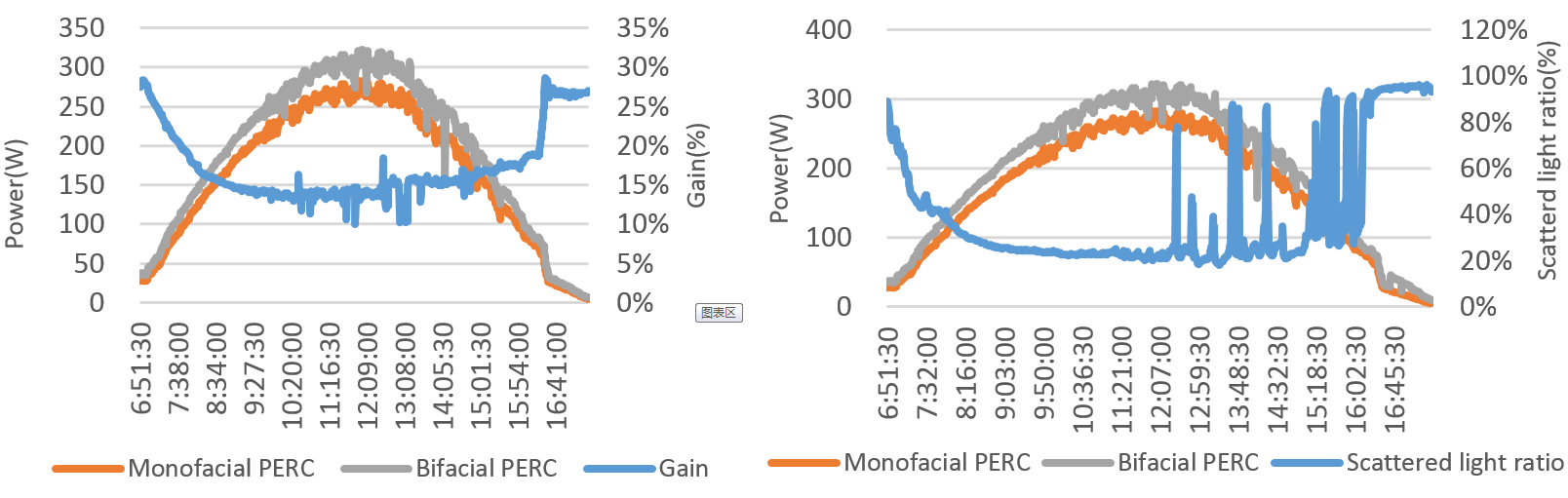

Then we selected a clear day to show the difference between the power generation gain and the scattering ratio in different time periods. It can be seen that the power generation gain of the PERC bifacial modules during the day is relatively stable, due to the high proportion of scattered light in the morning and evening, the curves of the two power generation gain tilted up.

Figure 5. Generation gain and scattering ratio of PERC bifacial modules at different times of a typical clear day (2018.11.14)

4) Performance Ratio

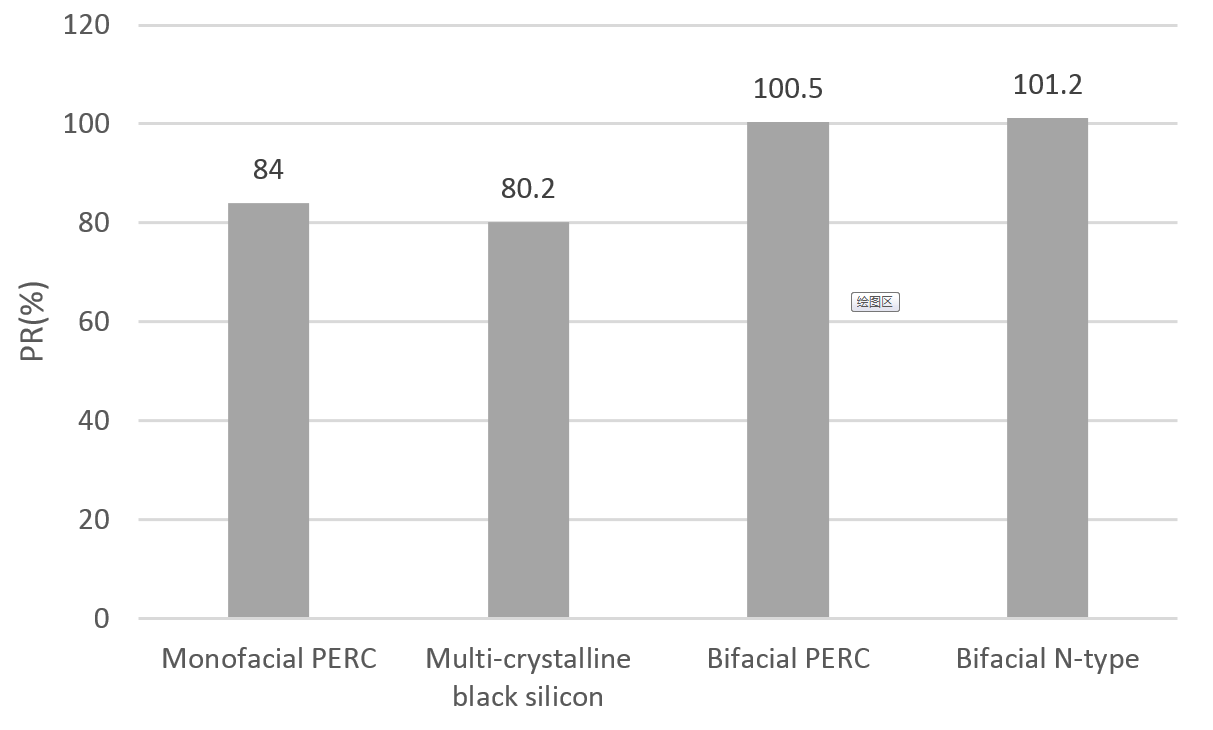

Figure 6 summarized the PR values of four modules in 6 months. The PR values of all modules are above 80%, and both LONGi’s bifacial PERC and N-type bifacial modules are above 100%, showing obvious advantages in efficiency.

Figure 6. PR values of four modules of the pilot project in India (September 2018 - February 2019)

In summary, in the tropical monsoon climate on the east coast of India, LONGi’s monofacial PERC module generates more than 3% of the power generation of the multi-crystalline black silicon module, the energy gain of P-type PERC bifacial and N-type bifacial module can reach more than 20% of multi-crystalline black silicon module on the white gravel surface condition. The power generation performance of P-type bifacial PERC module and the N-type bifacial module with higher bifaciality are at the same level, however the cost of P-type bifacial PERC is more competitive than N-type bifacial. With the expansion of production capacity and cost of monocrystalline PERC cells and modules decrease, PERC modules will soon dominate in the Indian PV market.