Since its founding 18 years ago, LONGi Solar is dedicated to the continuous development of mono technology. Today’s its Hi-MO range of monocrystalline PERC modules leads the industry with high power, low LID and high energy yield. Hi-MO3, the latest addition to the family launched in 2018, is a next generation bifacial module built with monocrystalline half-cut cells. Hi-MO2 offers the same bifacial mono-crystalline PERC technology in a traditional full cell layout.

The photovoltaic industry has entered a “high-efficiency era” with bifacial PERC becoming the mainstream technology. Based on a mono PERC cell, research engineers in LONGi solar pioneered a change in the printing technique with the use of local aluminum fingers on the rear side. This allows incident light on the rear of the panel to enter the cell and realize bifacial photoelectric conversion. Unlike the all-aluminum opaque rear side of monofacial PV modules, bifacial modules have higher total power generation efficiency.

As of August, 2018, LONGi R&D has exceeded 23% front-side efficiency of its bifacial PERC cell, while rear-side efficiency reached 18% and bifaciality surpassed 82% - all industry-leading milestones.

LONGi Solar is amongst a select handful of PV manufacturers with the technical knowledge, experience and financial strength to take its R&D laboratory achievements to mass production. Dr. Lv Jun, Vice President of LONGi Solar, said: “The development pace of the efficiency of bifacial cell is amazing. So far, mass production efficiency of bifacial cell has exceeded 22%, increasing up to 0.2% every six months while bifaciality has remained above 75%.”

In addition to efficiency improvement, every LONGi Solar bifacial modules have inherently superior performance due to lower operating temperatures. Dr. Lv Jun added, “We have been researching the application performance of bifacial modules. Our field tests in Taizhou, China showed average operating temperature of bifacial PERC modules to be 1~2℃ lower than that of monofacial PERC modules and the maximum operating temperature of bifacial PERC modules is 3~6℃ lower than that of conventional PERC modules.” The excellent low operating temperature and low irradiation performance directly translate to higher power generation.

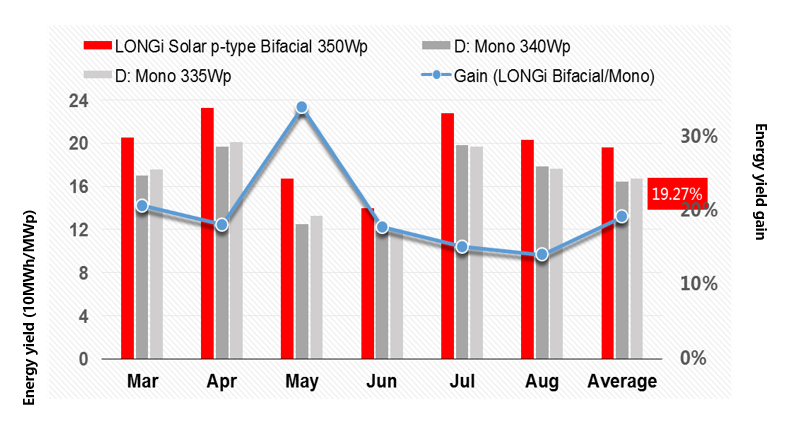

By their design, bifacial modules significantly increase the energy yield of power stations by 5%~30%, depending on the environment. The gain from bifacial modules also varies in different regions and is strongly correlated with ground surface reflectivity, installation height, latitude, module size, mounting, and inverter choices in the design of the bifacial system. LONGi Solar has done extensive fields tests in power stations, comparing bifacial and monofacial module performance on standard and single-axis tracking systems. On the cement ground of a power station in Taizhou, bifacial PERC yields 11% more energy than monofacial PERC modules. In the horizontal-single-axis tracking system of a power station in Qinghai, bifacial PERC yields 19.27% more energy than a conventional product. And under inclined irradiation conditions in a power station in Turpan, bifacial PERC module yields 23% more energy than a monofacial module. These rich test data are essential in modeling energy yields in bifacial modules and contribute to the bankability of LONGi Solar products.

As winter approaches in the northern hemisphere, the snowy conditions will significantly increase the energy yield of bifacial PERC modules. Tests by LONGi Solar showed energy yield increase of 62%~188% during snowfall, 272%~603% during snow melting, and 14%~34% when snow-free. In addition, bifacial PERC modules can significantly reduce the snow-melting time, and reduce the energy loss and reliability risks caused by snow.