In recent years, LONGi’s monocrystalline modules have been recognized by global customers for their excellent performance and reliability, leading to fast-growing shipments, industry-leading brand awareness and product bankability. This article will reveal how the reliable quality of LONGi’s modules is created from the aspects of product design, manufacturing and testing.

1. Module Design

1.1 Design and Simulation

LONGi’s module design fully combines theoretical modelling, experimental results and historical experience, comprehensively considering efficiency, power generation capacity and reliability in various scenarios. LONGi’s product research and development center has established optical, electrical and mechanical models related to the design of photovoltaic modules, to carry out corresponding simulation calculation at the initial stage of product design, and choose the solution with the best comprehensive performance according to the results. In the fundamental research into new photovoltaic materials, testing and analysis of photovoltaic devices, product reliability and system integration, LONGi has forged an in-depth research cooperation with scientific research institutions such as the University of New South Wales in Australia to provide guidance for new product development.

1.2 Material Selection and Testing Standards

For the selection of module materials, LONGi has always maintained a highly cautious approach, usually preferring materials that have already been fully validated by the industry. For new materials and corresponding processes, LONGi carries out more rigorous evaluation and verification: first of all, it makes a theoretical analysis of the material’s performance, based on its composition and structural characteristics, followed by targeted and stringent tests. Finally, the module containing the material must pass a reliability test to a level which is twice (or even 3 times) more demanding than the IEC standard, only being approved for use after its successful completion.

In terms of selection of its suppliers, LONGi insists on cooperating with organisations with an industry-leading reputation and guarantee of long-term operations, to ensure the stability and reliability of material performance. With a corporate culture of being “reliable, value-added and fair”, LONGi advocates equality in dealing with supply chain partners, a win-win cooperation and innovation to promote the progress of both products and the industry in general.

1.3 Performance Verification

In addition to theoretical analysis and laboratory tests, the evaluation of the reliability and power generation capacity of photovoltaic modules also needs to be supported by outdoor test results. LONGi’s product research and development center has a 200kW field test station for special research, such as energy gain on the rear of bifacial modules in different application scenarios, light-induced and medium and long-term degradation of modules, anti-PID performance, shading analysis, analysis of working temperature and module hot spots. For research into the outdoor field test performance of modules under various climatic conditions, LONGi has successively cooperated with authoritative institutions including the China Electric Institute, TÜV SÜD, TÜV Rheinland, RETC, the China General Certification Center and DNV GL, and set up field test power stations in different locations around the world to fully verify performance under different conditions. These field test power stations have obtained a great deal of valuable data and provided strong support for the verification and analysis of the reliability of products and materials.

2. Module Manufacturing

2.1 Comprehensive Quality System and Quality Control

LONGi has a comprehensive quality control system, and has obtained ISO 9001 and IEC TS 62941 certifications in the photovoltaic field. Quality management covers processes such as supplier management, new product development, product change, product production and test equipment measurement. With respect to production, quality and equipment information are collected through the MES (Manufacturing Execution System). The quality control of a factory is highly respected by customers and third-party factory auditors.

2.2 Advanced Manufacturing Capacity

LONGi’s 10GW-class cell and 20GW-class module capacity have both been built in recent years and high levels of automation not only greatly improve production efficiency, but also help to ensure the stability of the production process.

In addition, compared with other manufacturers in the industry, LONGi has a better product structure. At present, the mainstream products are the Hi-MO4 series and the half-cell monofacial and bifacial modules based on M6 silicon wafers. M2 half-cell modules will exit the market after delivery of existing orders. Unified product specifications bring great convenience for material procurement, product production and inventory management, and are also conducive to the optimization of product quality.

2.3 Reliable Supply

LONGi has the largest module production capacity in the world, and can meet client-side demand from its own capacity, without the need for OEM. As a vertically integrated enterprise, LONGi adopts only high-quality, low-degradation silicon wafers, which, when coupled with a high level of in-house cell supply, guarantees module quality.

In line with the “reliable” corporate culture, LONGi has always communicated openly with customers on issues such as supply capacity and technical parameters without making false promises. In the rush-to-install period with tight supply in the industry over the years, LONGi has effectively supported customers to put their projects, including “Top Runner” projects, on grid on schedule, and have therefore earned their support and trust.

3. Reliability Testing

3.1 In-house Reliability Testing

As mentioned in 1.2, LONGi tests the reliability of new products according to 2~3 * IEC standard, and for the passing standard of 1 * IEC test, LONGi’s internal control index is much stricter than the common degradation (< 5%) in the industry. In addition, LONGi has established a variety of differentiated reliability testing methods based on the research results of well-known institutions and third-party bodies in the industry. Here are 3 examples:

A. HATC (Highly Accelerated Thermal Cycling)

TC (Thermal Cycling) testing is to verify the welding performance of products under certain temperature changes. The analysis and study of the key influencing factors of a TC test shows that increasing the maximum temperature (Tmax) of the test is helpful to quickly evaluate the aging lifespan of products under thermal cycling. Therefore, LONGi introduced HATC into the reliability test, increasing the Tmax from 85 °C to 125 °C. The lifespan of a product assessed by HATC is 2.9 times that of one assessed by IEC TC. HATC can not only evaluate the weldability of modules more quickly, but also help to find failure risk points that cannot be identified in the conventional IEC standard test. This is due to more stringent condition settings and ensures a more comprehensive evaluation of product reliability.

B. UV+DH Ageing

In the IEC standard test, UV (ultraviolet) or DH (damp heat) tests are conducted separately to evaluate the damp heat stability of the module, which is quite different from the outdoor environment. When working in the corresponding area, the module is not only in a damp heat environment, but is also subjected to solar irradiation. In order to better and more strictly simulate the service condition of module materials in an outdoor environment, LONGi introduces a UV+DH ageing test. The UV and DH tests are carried out at the same time to evaluate the long-term outdoor service of module materials, and represent a more stringent and typical set of testing criteria.

C. Cell-side Metal Corrosion Testing

According to the degradation curve of a module in long-term outdoor service, the main failure mode in the stable and later stage is power degradation caused by interior cell metal corrosion, which is difficult to evaluate via the IEC standard test. In order to assess the corrosion of cell metal more effectively and quickly, LONGi carries out a cell-side electrochemical (positive and negative bias) corrosion test in an acetic acid solution by simulating a DH or PID test connection mode to verify the corrosion of cell surface metal, assess the possible corrosion risk points of modules in long-term outdoor service, and design reliability to minimize the outdoor metal corrosion risk and improve long-term reliability.

3.2 Third-party Accredited Enterprise Lab

LONGi’s Taizhou module test lab not only has CNAS certification, but also meets the ISO/IEC 17025:2017 standard criteria. It has also been certified by institutions including the China Quality Certification Center (CQC), the China General Certification Center (CGC), TÜV Rheinland, TÜV SÜD, CSA and UL. Accurate testing and measurement ensure the accuracy of the reliability analysis conclusions.

3.3 Third-party Evaluation of Module Quality

Over the years, LONGi’s modules have achieved excellent results in third-party testing and evaluation:

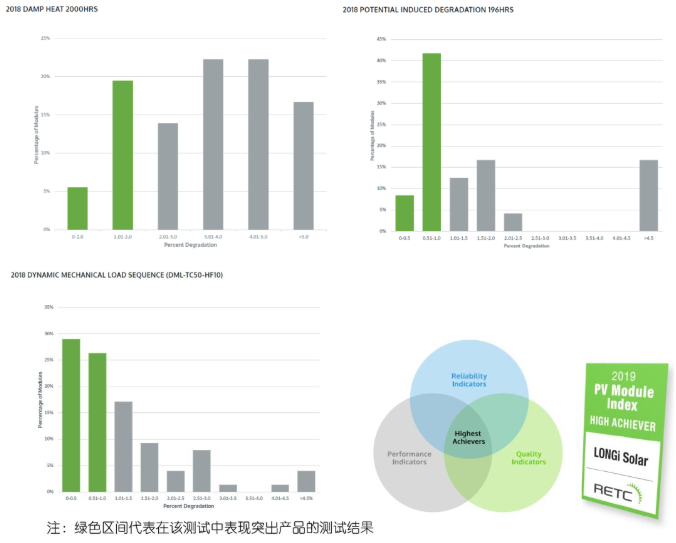

A. RETC 2019 (High Achievers in PV Module Index 2019 edition)

In order to enter the US market, photovoltaic modules usually need to pass stringent reliability tests higher than the IEC standard in laboratories including RETC and PVEL. RETC (Renewable Energy Test Center) released their PV Module Index report for the first time in 2019, based on the data of more than 2,500 crystal silicon and thin film modules from 46 companies tested in 2018. The products of LONGi and Panasonic delivered an outstanding performance in the evaluation of the three major indicators and won the high achievers award. The tests involved in the evaluation included TC600, DH2000, HF30 (Humidity Freeze), DML+TC50+HF30, PID196h; module efficiency, Pan File & energy yield simulation and LID. LONGi’s modules performed well in all tests.

B. AON test

In 2018, Japan’s AON insurance company commissioned TÜV Rheinland Japan to evaluate the long-term reliability of LONGi’s single-glass modules. Testing included HATC, stringent hot spot endurance and backplane endurance sequence testing (DH800+UV60+TC200+static load). The subsequent report concluded that the annual degradation of LONGi’s single-glass module is 0.31% / year, which is less than the warranty value (0.55%).

C. TÜV Rheinland “All Quality Matters” award

TÜV Rheinland began to host “All Quality Matters” events at the end of 2016 to evaluate photovoltaic products. Photovoltaic modules are selected from 1,000 mass produced modules for Pan file testing, simulating power generation in five cities around the world (later adding outdoor power generation comparisons). Among the three events organized from 2017 to 2019, LONGi won first place in energy yield simulation in the monocrystalline group in 2017 and 2018 (the simulated energy yield is more than 1.5% higher than the first place in the polycrystalline group), and won first place in the monofacial group in the outdoor power generation field test in 2019.

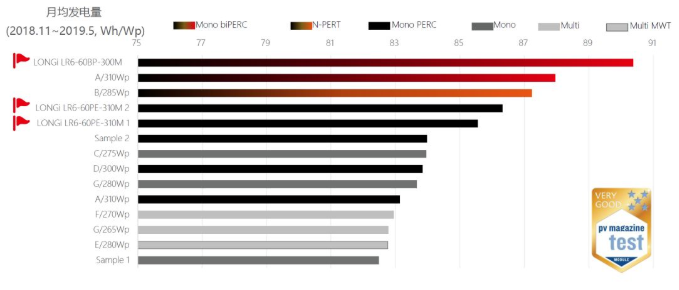

D. PV Magazine test

The German PV Magazine Group, in conjunction with the American CEA and Chinese Gsolar, took samples from 2,000 modules to test their performance and carry out outdoor power generation field testing. LONGi’s PERC monofacial and bifacial modules were found to be far ahead of similar products in terms of energy yield, demonstrating their excellent power generation capacity and anti-degradation performance.

A photovoltaic project is an investment that lasts for more than 20 years, and reliable products can bring long-term ROI for investors. Reliable products come from reliable companies. In the process of its long-term operation and accumulation, LONGi always gives priority to its financial health and enterprise robustness, maintaining fast-growing shipments in many markets around the world. With reliable products and leading technology, LONGi continues to create higher value returns for both customers and partners.

Download the PDF whitepaper here: https://bit.ly/3ctOG9y