China is widely recognized as the centre of the world’s PV module manufacturing, shipping to every corner of the globe via sea, road, rail and air. With factors such as delivery cycle, capacity and cost to be considered, sea transportation has become the preferred mode for shipping and, with this being the case, how to maximize utilization of container capacity is now a key area of focus for design engineers.

I. Packaging Methods for PV Modules

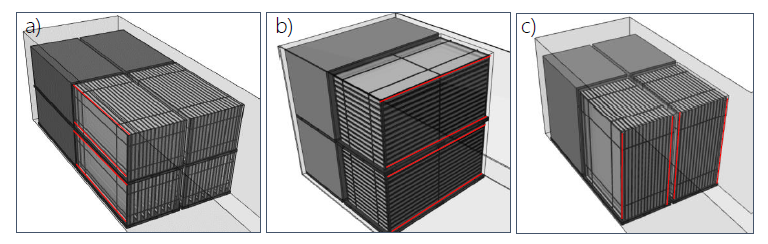

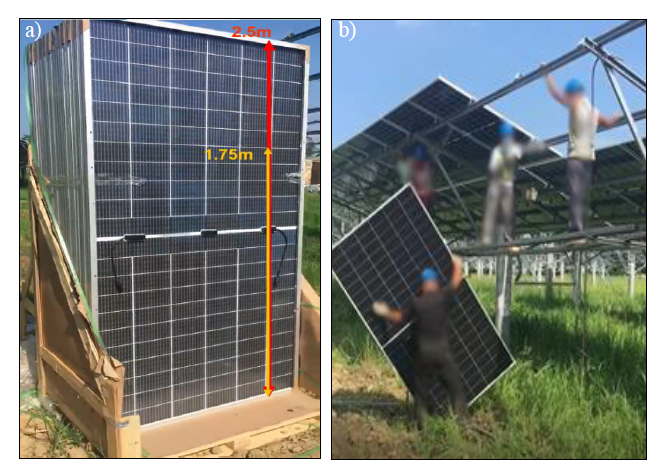

Figure 1. Three packaging methods for PV modules: a) Landscape vertical packaging is recognized as optimal; b) Horizontal stacking has been eliminated; c) Portrait vertical packaging is applied for larger PV modules.

Vertical packing is commonly viewed as the optimal method, coming about from issues with the horizontal stacking alternative. Upright packaging resolves the three key problems with horizontal stacking, namely module frame deformation, glass breakage and invisible cracks caused in transit and the landscape vertical solution has become the common choice over the portrait alternative.

II. Maximum Permitted Size with Landscape Vertical Packaging

Satisfying the ultimate objective of reducing the ratio of products either broken or with invisible cracks on arrival, landscape vertical packaging has a lower barycenter with the resultant lower risk of modules overturning during packing and unpacking, due to its design advantage for operational safety performance. This is the key reason for its preferred status, better meeting the requirements for reliability during sea transportation, the stability of packaging and the safety of employees involved.

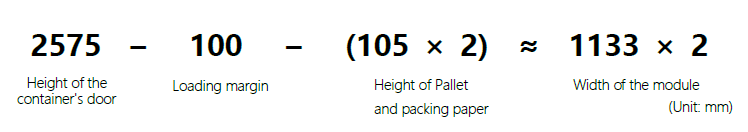

According to the height of a container door, the maximum permitted height for optimal packaging can be determined. The logical relationship is shown below:

In line with an optimal product width of 1,133 mm and the symmetrical style of a module's design aesthetics, LONGi launched its 182 mm×182 mm wafer-cell and Hi-MO 5 series products, designed specifically for the entire industrial chain and to maximize value for customers.

Figure 2. Pictures of PV module transportation, loading and unloading placement: a) Hi-MO 5 product is loaded into the container in the factory, with a forklift operating margin of about 10 cm; b) the container is delivered to a project site with uneven ground; c) the landscape vertically packaged modules can be placed stably in different situations.

III. Portrait Vertical Packaging Issues for Large-size PV Modules

· The operational margin for container loading and unloading is extremely limited, with theoretically only about 7 cm available.

Hi-MO 5 products are designed to present a 10 cm operating margin for container loading and unloading. However, this redundancy in operating height for larger modules in a portrait vertical packaging scenario is reduced to around 7.0 cm once height, thickness of packing paper and pallet height are taken into account, meaning that overall height will exceed 2.5m, with that of the container door 2.575m. While goods packed tightly can be loaded and unloaded by skilled workers in a factory environment with equipment such as a cargo platform, there are no such facilities available at overseas warehouses or project sites.

· Workers are at greater risk of injury from overturning packages with higher weight and barycenter

Compared with the bifacial Hi-MO 5’s weight of 32.3 kg, the weight of a larger module exceeds 38.7 kg, an increase of almost 20%. Larger modules are also packed via the portrait vertical method, meaning that the height of the package will exceed 2.5 m (see Figure 5a.). The height of the barycenter is almost doubled compared with the Hi-MO 5, increasing the possibility of overturning and subsequent injury.

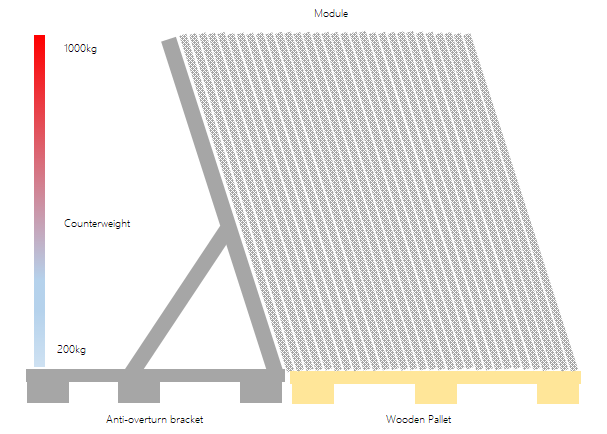

Figure 3. To prevent overturning of portrait vertical packaging, anti-overturn support and hundreds of kilograms of counterweight are required, which is difficult to obtain at a project

Taking an initial tilt angle of 75° as an example, larger module weight is 38.7 kg, with one pallet of 31 units having an overall gravity as shown below:

G = 38.7 × 31 × 9.8 ≈11760N

The pressure on the bevel side of bracket:

F = G × cos75° ≈ 3043N

The static friction coefficient between the bracket and sand is taken to be 0.4, with its balance relationship with the horizontal force as follows:

Fmax = (Mbracket × 9.8 + F × cos75° ) × 0.4 ≥ F × sin75°

According to the above, bracket weight needs to reach more than 660 kg in order to retain non-slip status, with use of a bracket of this weight at a project using larger modules a challenge during the construction and installation phases.

Bracket weight can also be calculated under different tilt angles, with the smaller the angle of unpacking, the higher the risk of bracket slippage.

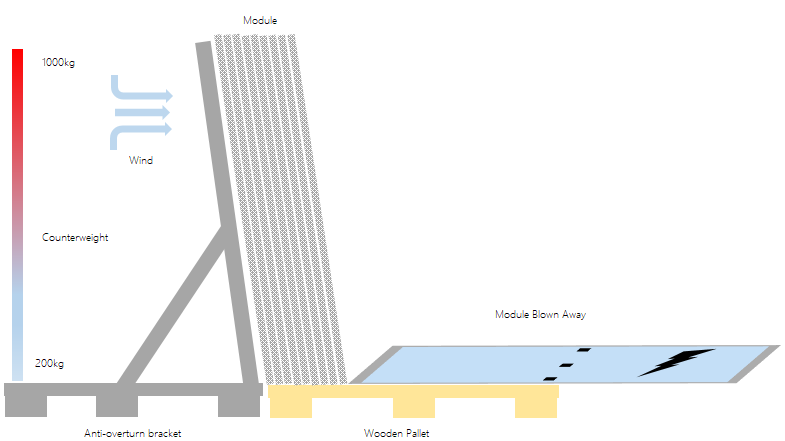

If an installer is unpacking, modules may also be overturned by wind reaching the fifth scale when the number to be unpacked is less than 10 units and the tilt angle over 85° (e.g., figure 4.) In summary, larger modules packed in a portrait vertical method are at greater safety risk, with additional limitations in terms of bracket unpacking at ground mounted PV plants.

Figure 4. Schematic diagram of unpacking of modules in portrait vertical method, with support bracket against wind

· The ground mounted PV plant has poor terrain adaptability, lower efficiency in drayage and higher construction and installation costs.

During the initial stage of construction of a large-scale ground mounted PV plant, care needs to be taken to position packaged modules so as to avoid them overturning, which makes drayage more difficult on uneven ground. Compared with the per pallet weight of Hi-MO 5 bifacial modules, that of larger modules shows an increase of 20%, resulting in a net weight of over 1.2 tons. For this reason, a forklift or hoisting machinery with a large load capacity is required for safe drayage, adding to labour and equipment costs to complete installation within the construction period.

For installation of larger modules, there is also a possibility of lower efficiency and a higher invisible crack rate. As shown in Figure 5b, it can be difficult for workers to handle a larger module, needing to place a corner on the ground, with the additional concern of exceeding the recommended maximum weight of just under 35kg for handling by two people (the maximum weight for handling by one person is 20kg to 25 kg, with the coefficient for two people 0.666, i.e., 25 × 2 × 0.666 = 33.3 kg (refer to HSL Guide for Weight Limit in Manual Handling)).

Figure 5. Unpacking and installation of larger modules: a). The packaging height is much higher than the installer; b) Size is too large and wide, leading to lower installation efficiency and potentially higher breakage rate.

According to research, the breakage rate of the Hi-MO 5 bifacial module is generally lower compared to that of larger modules during installation, whereas the invisible crack rate for larger modules increases more than fivefold.

In conclusion, LONGi adheres to the proven reliability of the landscape vertical packaging solution for its Hi-MO 5 modules, this both minimizing sea transportation costs and making unpacking and installation more convenient for workers onsite.

About LONGi

Founded in 2000, LONGi is committed to being the world’s leading solar technology company, focusing on customer-driven value creation for full scenario energy transformation.

Under its mission of 'making the best of solar energy to build a green world', LONGi has dedicated itself to technology innovation and established five business sectors, covering mono silicon wafers cells and modules, commercial & industrial distributed solar solutions, green energy solutions and hydrogen equipment. The company has honed its capabilities to provide green energy and has more recently, also embraced green hydrogen products and solutions to support global zero carbon development. www.longi.com