Bifacial PERC module has excellent application prospect in America, where the light resources and flat terrain are abundant. In order to verify the energy yield performance of bifacial PERC module in this area, and also to improve the bankability of bifacial PERC module, LONGi cooperated with B&V(Black & Veatch)and RETC(Renewable Energy Test Center)to build three pilot projects in America in 2018. Recently, LONGi received the final reports for these pilot projects, therefore this whitepaper will show the energy yield performance of LONGi’s bifacial PERC module.

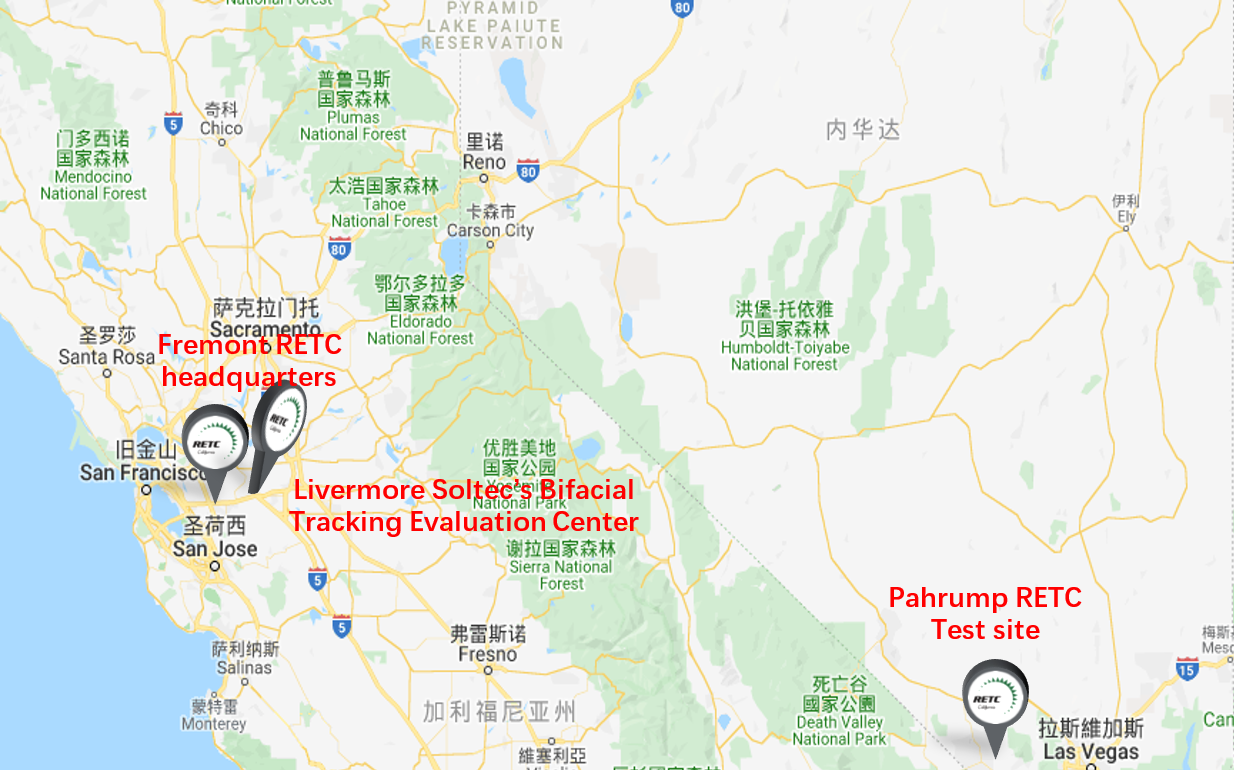

The three pilot projects were located at different places with different installation types. The modules of Fremont pilot project were placed on fixed tilt racking located on the roof of the RETC headquarters building in Fremont, California. The modules of Livermore pilot project were mounted on Soltec model SF7 bifacial single axis tracker located at Soltec’s Bifacial Tracking Evaluation Center (BiTEC) in Livermore,California. The modules of Pahrump pilot project were placed on a fixed tilt racking system located at the RETC test site in Pahrump, Nevada. The detailed information can be seen as follows:

Figure 1. The distribution of pilot projects

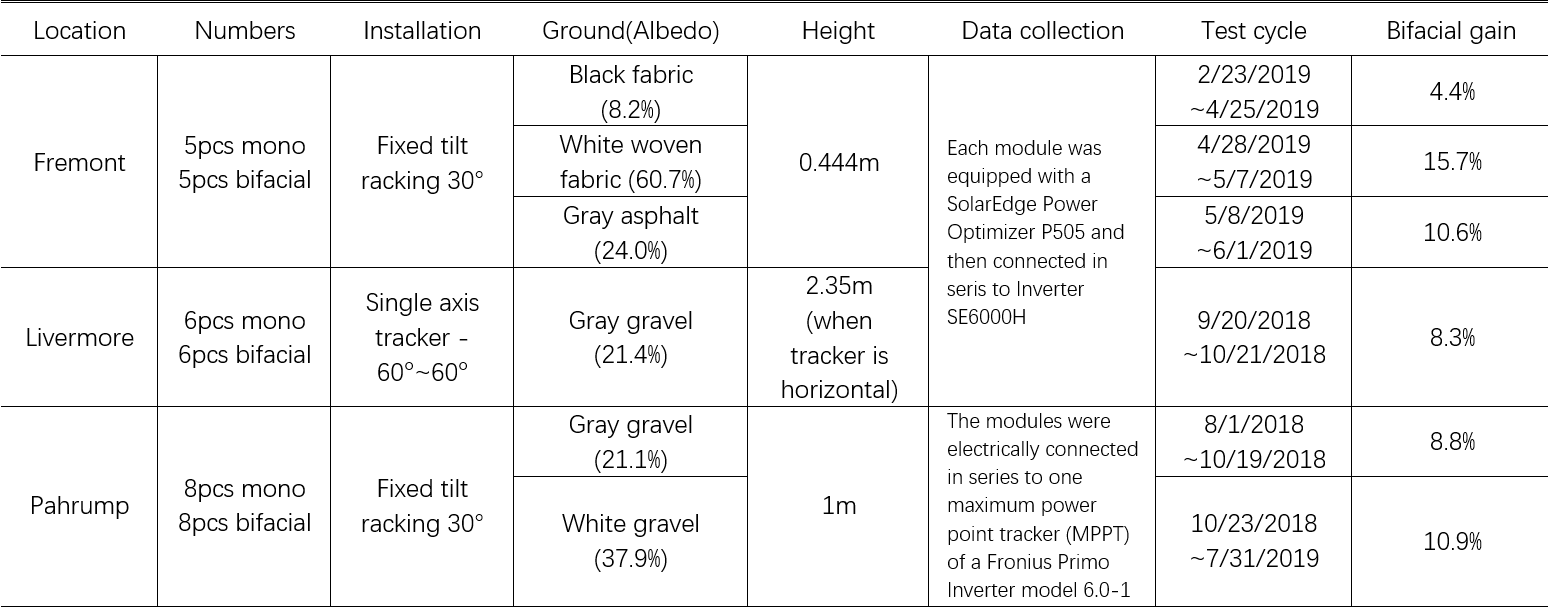

Table 1. Summary of pilot projects

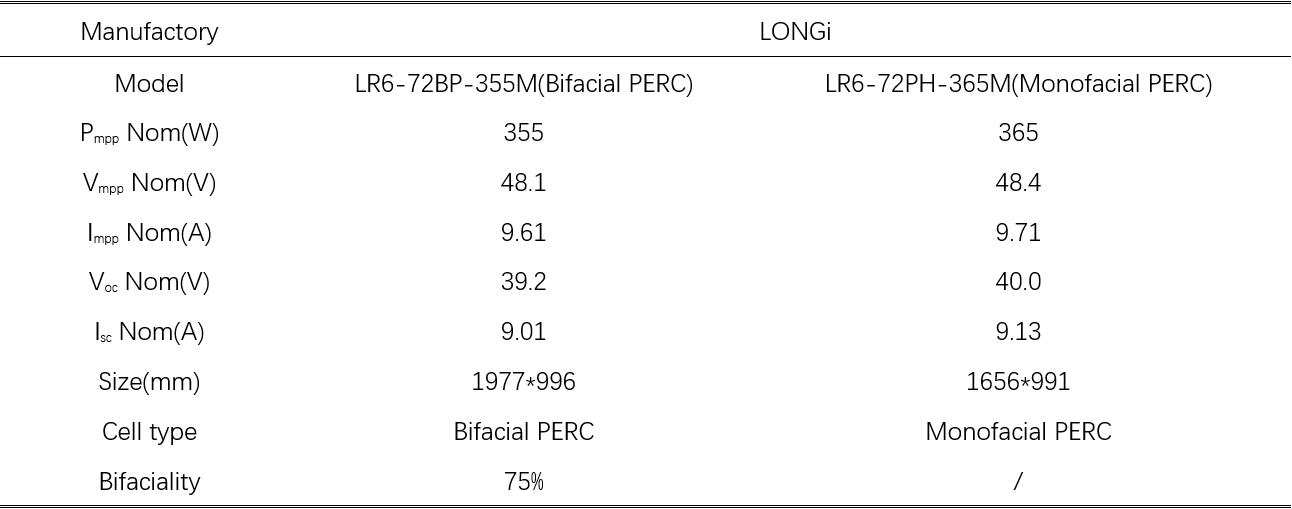

Table 2. The IV parameters and size of modules

Then the array layout and test results for three pilot projects will be introduced.

1) Fremont pilot project

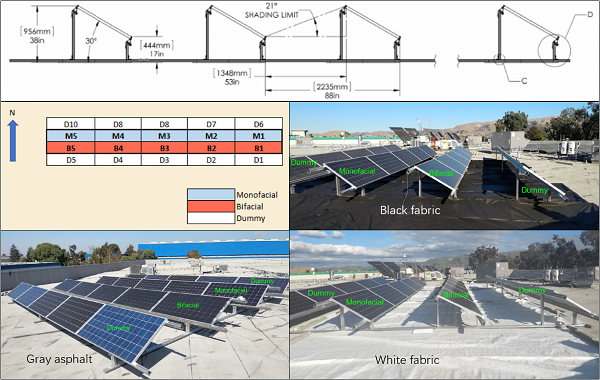

The modules of Fremont pilot project was located atp the roof of RETC headquarters building in Fremont, California (N 37.5, W122.0). The array layout is shown as figure 2. In order to ensure the monofacial and bifacial modules have the same shadow condition, additional Dummy modules were placed in the 1st and 4th row. Each module was equipped with a SolarEdge Power Optimizer P505 and then connected in seris to Inverter SE6000H for calculating the energy yield of each module (Average data was used for the comparison of energy yield).

Figure 2. The array layout and photos of Fremont pilot project

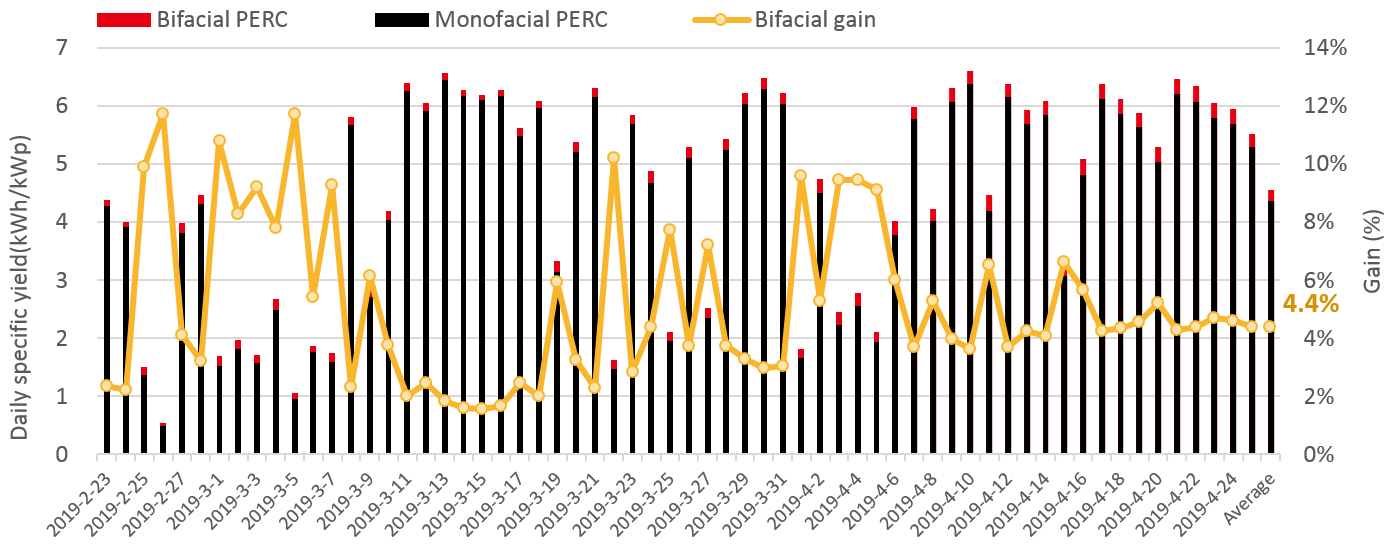

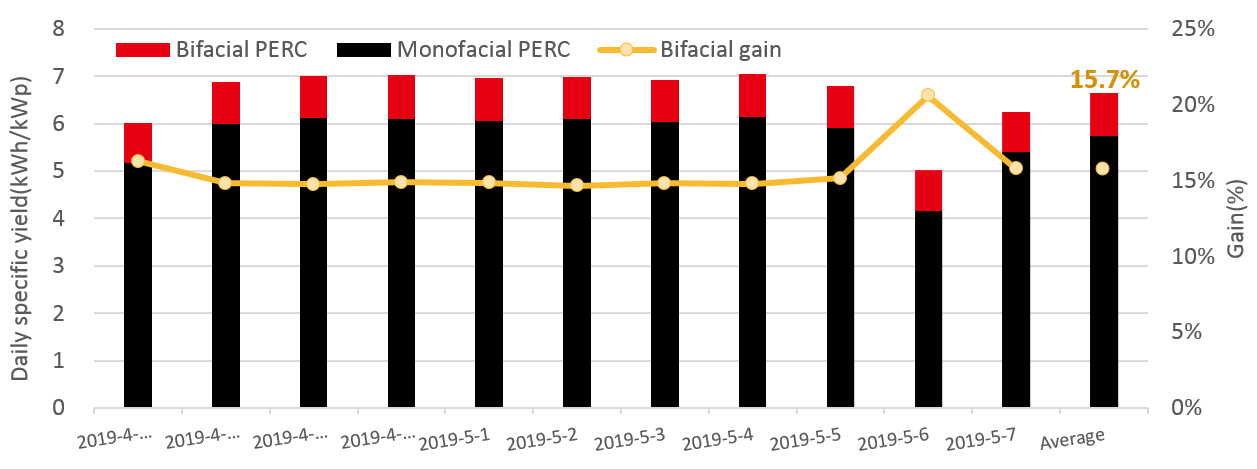

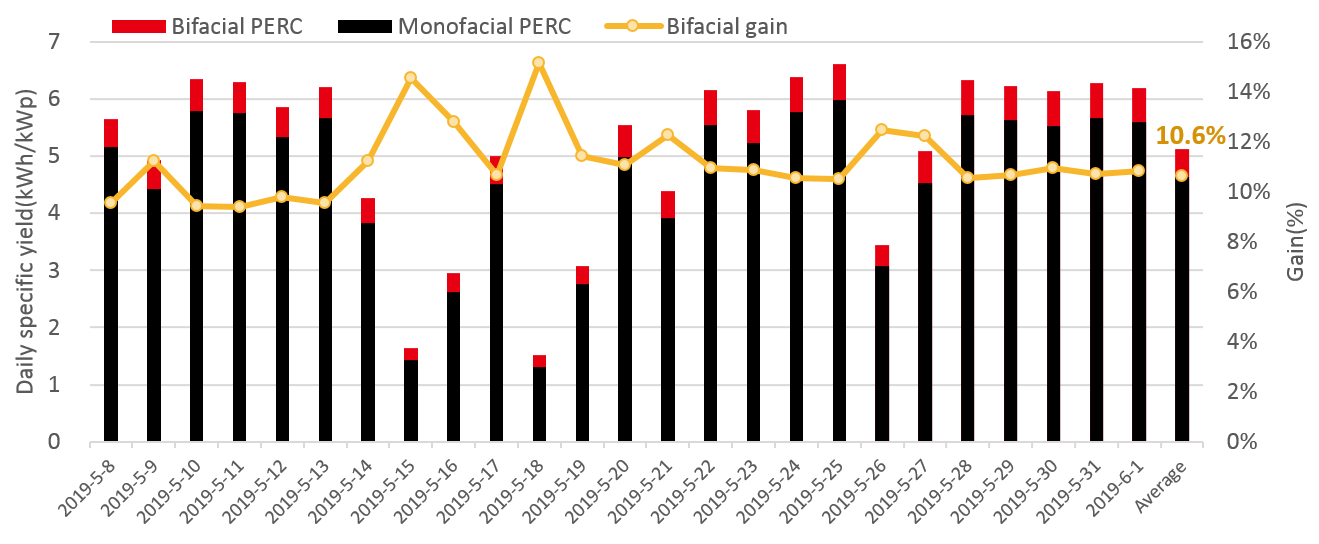

The test period for Fremont pilot project was from Feb 23th, 2019 to June 1st, 2019. Since the modules were placed on the roof of RETC headquarters, RETC could easily change the ground surface to evaluate the correlation between the ground Albedo and bifacial gain. The ground and surface Albedo were black fabric (8.2%), gray asphalt (24.0%), white fabric (60.7%), the bifacial gain in the corresponding period was 4.4%, 10.6%, 15.7% respectively as shown in Figure 3 to Figure 5. The fluctuation of bifacial gain curves is attributed to the scattered light ratio, In the cloudy days with high ratio of scattered light the energy yield was low, however the bifacial gain was high. This phenomenon was much obvious in the black fabric ground surface. It should be noted that the project used common low rack for roof, where the installation height was 0.444m. If the installation height was 1m higher, the bifacial gain could be higher. Gray asphalt was the original ground material, in which case the 10.6% bifacial gain reflected the considerable application value for bifacial modules.

Figure 3. The daily specific yield and bifacial gain on black fabric ground in Fremont pilot project.

Figure 4. The daily specific yield and bifacial gain on white fabric ground in Fremont pilot project.

Figure 5. The daily specific yield and bifacial gain on gray asphalt ground in Fremont pilot project.

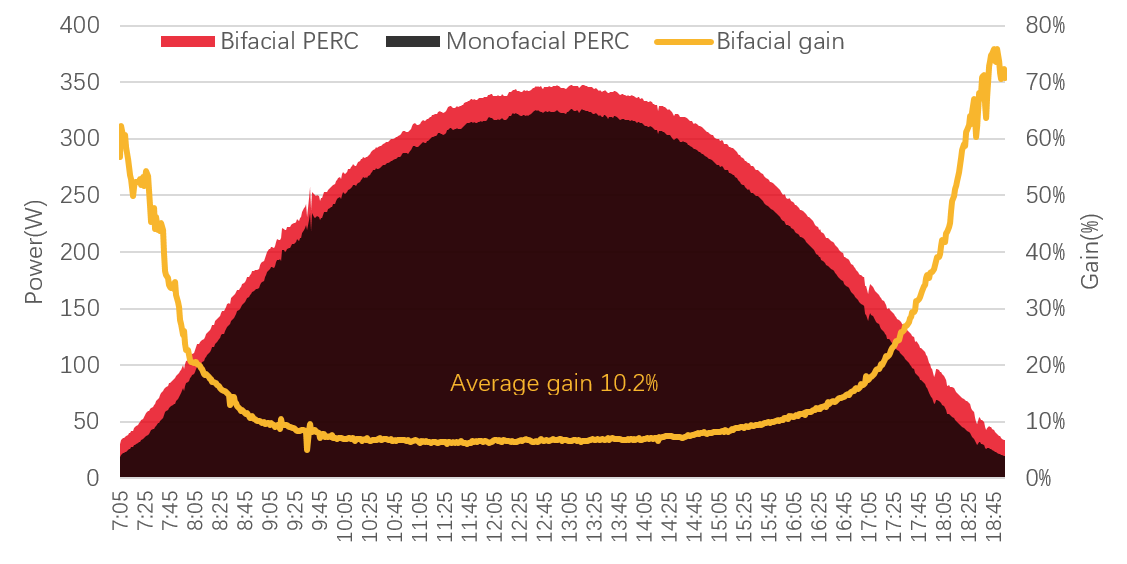

Figure 6 showed the output power and bifacial gain for bifacial and monofacial PERC modules in typical sunny day (Gray asphalt ground). It could be seen that bifacial gain was stable during 10am to 2pm (6%-7%). The bifacial gain curve tilted in the morning and afternoon because of its high scattered light ratio, the highest bifacial gain could be above 50%. Besides the average bifacial gain was 10.2% for the whole day. In the noon the bifacial gain was about 6%, which is beneficial for matching inverters.

Figure 6. The output power and bifacial gain for bifacial and monofacial PERC modules in typical sunny day (fixed tilt racking)

2) Livermore pilot project

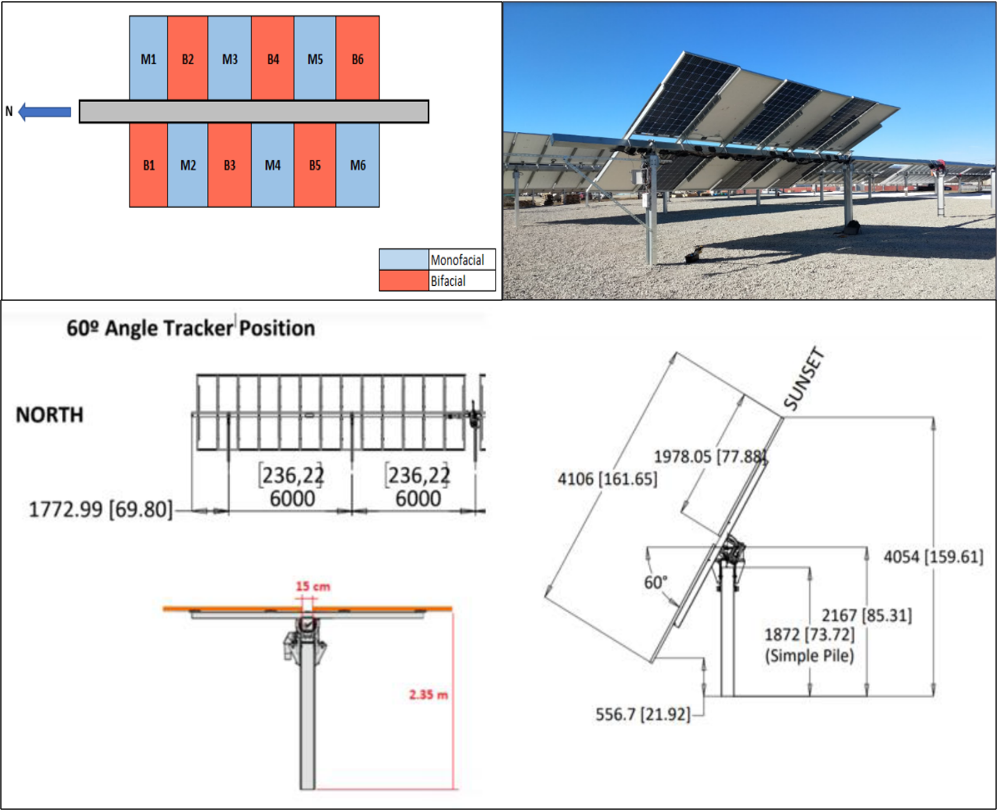

The modules of Livermore pilot project were mounted on Soltec model SF7 bifacial single axis tracker located at Soltec’s Bifacial Tracking Evaluation Center (BiTEC) in Livermore, California (N37.7, W121.7). The array layout and racking design was shown in Figure 7: 12 modules were mounted on Soltec model SF7 bifacial single axis tracker, which is 2-Portrait (2P) type,The tilt angle of tracker was -60~60, the modules were mounted alternately in each row forming a checkerboard pattern. Each module was connected to a power optimizer to keep it at Maximum Power Point (MPP) operation. High precision DC measurement modules are used to measure the DC voltage and current characteristics of each module. The ground was covered with gray gravel, in which the Albedo is 21.4%.

Figure 7. The array layout and tracker design for Livermore pilot project

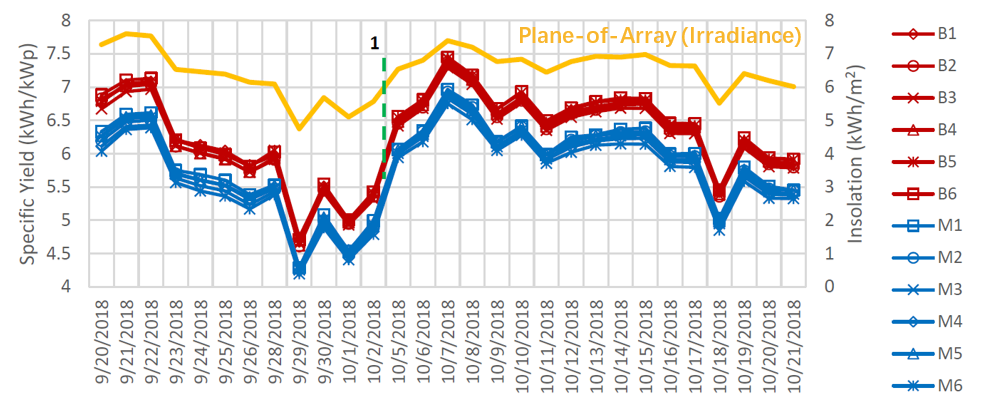

The test period was from Sep 20th,2019 to Oct 21th,2019,Figure 8 showed the daily energy yield for each module. It could be found that the energy yield for both monofacial and bifacial modules was uniform. The bifacial gain was calculated by choosing the average yield for each type module.

Figure 8. The energy yield for both monofacial and bifacial module was uniform in Livermore.

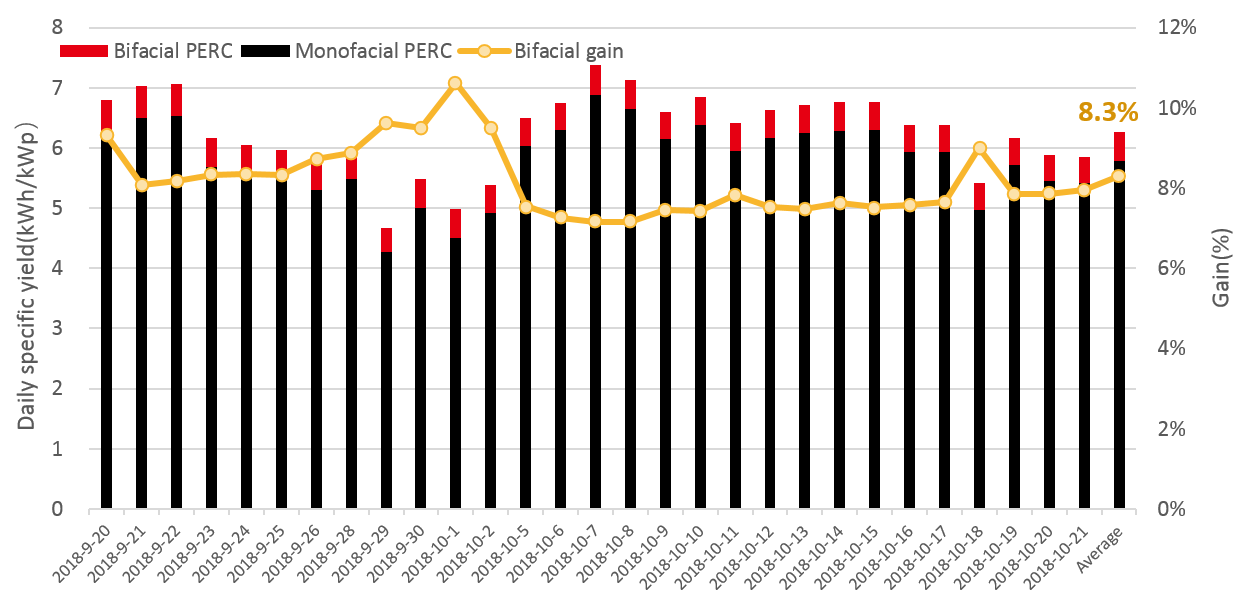

The comparison of monofacial PERC and bifacial PERC’s energy yield was shown in Figure 9. The bifacial gain during Sep 20th to Oct 21th was 8.3%. Considering the single axis tracker will increase the baseline for monofacial module, the 8.3% gain was very impressive in the gray gravel ground surface with 21.4% Albedo. For the desert ground with high Albedo, the bifacial gain will be above 10%. Many large projects used modules supplied by LONGi in desert. Where matching the bifacial modules with single axis tracker.

Figure 9. The daily specific yield and bifacial gain on gray gravel ground in Livermore pilot project.

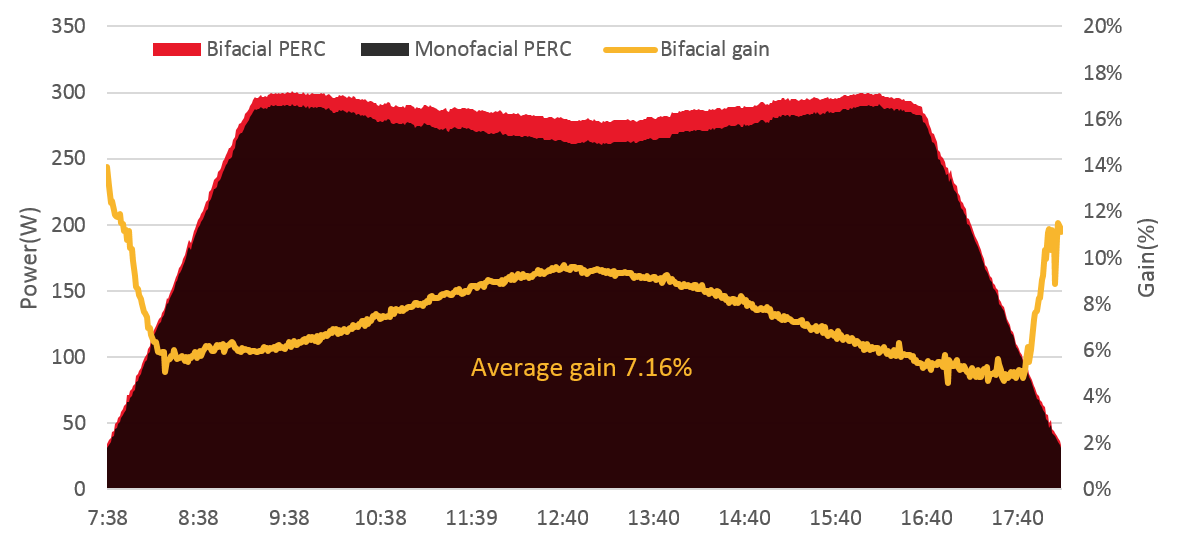

Figure 10 showed the output power and bifacial gain for bifacial and monofacial PERC modules in typical sunny day (Gray gravel ground). The bifacial gain curve tilted in the daytime for the single axis tracker, which is different from the fixed rack. The reason can be attributed to the array has the smallest shadow area in the noon. The single axis tracker made the output power very stable for about seven hours (during from 9:00am to 4:30pm), which will be more friendly to the electrical grid.

Figure 10. The output power and bifacial gain for bifacial and monofacial PERC modules in typical sunny day (single axis tracker)

3) Pahrump pilot project

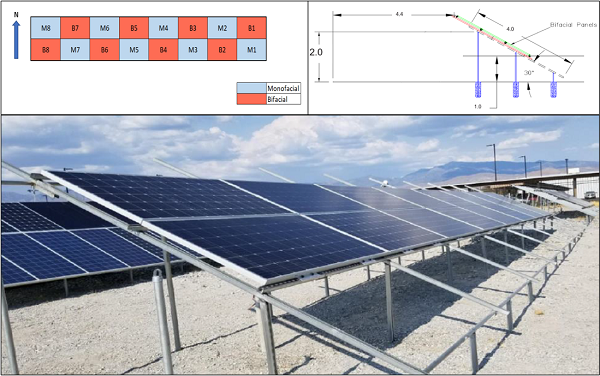

The modules of Pahrump pilot project were placed on a fixed tilt racking system located at the RETC test site in Pahrump, Nevada(N36.2, W116.0). The array layout and racking information was shown in Figure 11: The modules are installed facing due South on a fixed rack, tilted at 30⁰ from the horizontal, and connected to a dual-MPP inverter. The modules are installed alternately in each row forming a checkerboard pattern. Eight (8) bifacial modules are connected in one string to one MPPT input of the inverter and eight (8) monofacial modules in one string to the other MPPT input. High precision voltage transducers and current transformers are used to measure the DC power characteristics of the string. The project began from Aug 3rd, 2018, the ground surface was gray gravel with 21.1% Albedo. On October 20-22, the ground surface was changed to white gravel with an albedo ratio of 37.9%, an 18.3% more albedo than the gray gravel. The yield data was up to Jul 31th, 2019.

Figure 11. The array layout and photos for Livermore pilot project

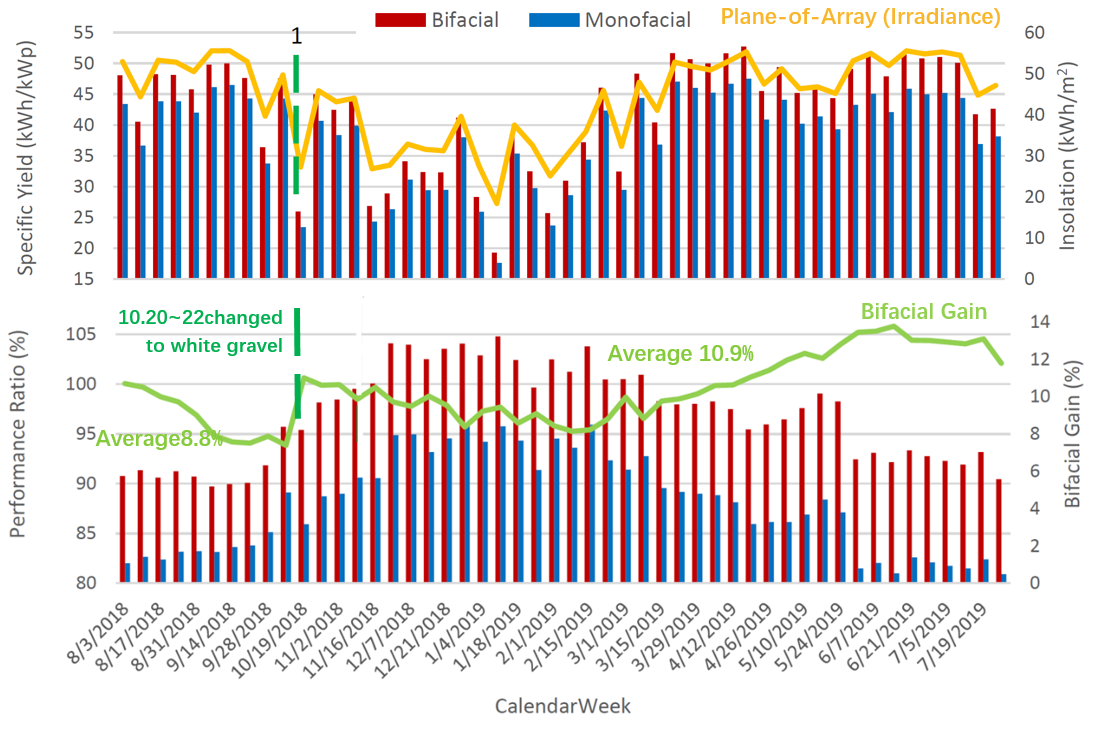

Figure 12. The weekly specific yield and bifacial gain in Pahrump pilot project.

The weekly energy yield for modules of Pahrump pilot project was shown in Figure 12. The average bifacial gain was 8.8% on the gray gravel ground (21.1% Albedo), when the ground surface changed to white gravel (37.9% Albedo) the average bifacial gain was 10.6%. The test period for white gravel was above 10 months, it could be found that the bifacial gain varied with the season changed: lowest in winter, highest in summer (8~14%). The reason is that the scattered light ratio was high in the morning and afternoon at summer time, besides the solar zenith angle varied periodically which will affect the array’s shadow area. Moreover the figure showed the performance ratio in winter was higher than that in summer mainly attributed to the big temperature difference in California, where the temperature in summer was about 30% higher than that in winter.

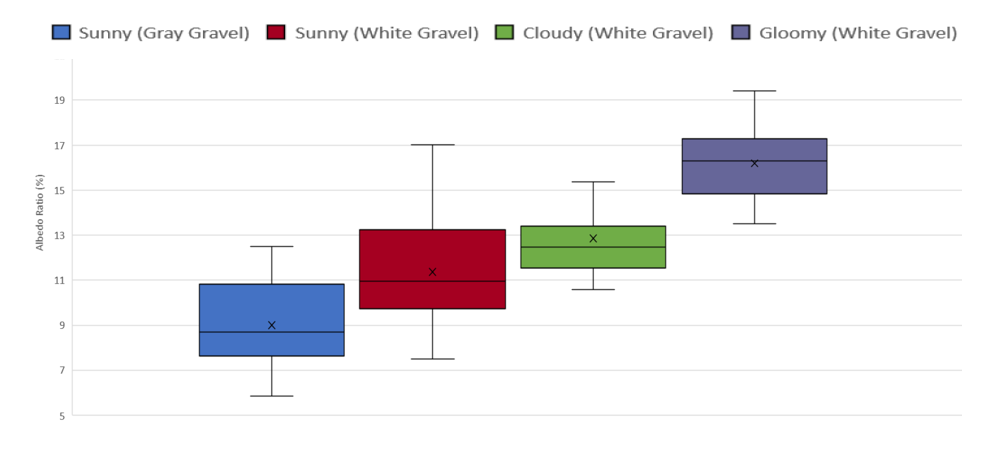

Figure 12 summarized the ratio of rear side irradiance to front irradiance under different weather conditions. It could be found that the ratio was lowest (~11%) in sunny weather, highest (above 15%) in gloomy weather. The reason is that the scattered light ratio in gloomy weather is high which can be received by rear side of module. When the rear side irradiance is higher, the bifacial gain will be higher.

Figure 13. The ratio of rear side irradiance to front irradiance at different weather.

Summary:

The three pilot projects built by LONGi together with B&V(Black & Veatch)and RETC(Renewable Energy Test Center)above have fully verified the advantage of bifacial PERC compared with monofacial PERC under different conditions by reasonable design. The test result can provide reference for the bifacial PERC application in large ground power station (using fixed tilt racking or single axis tracker), rooftop power station and floating power station. Besides it is beneficial for removing the doubts of investors and financing institutions, moreover it will be very helpful for large-scale application of LONGi’s bifacial PERC in the world.