The large-scale application of PERC technology, like a butterfly flapping the wings, has instigated changes in the entire industry. It is predicted that PERC will become a standard configuration in 2019.

With respect to cell technology, bifacial makes the PERC technology more cost-effective, and accelerates the progress of grid parity. Compared with the cell technology, the half-cut-cell module technology comes more easily and is easier to master. In addition, it requires smaller investment in equipment, is easier to realize mass production, and can solve the hot spot problem of modules. The bifacial PERC+half-cut-cell has become an important direction and key force to further improve the competitiveness of PERC.

Bifacial becomes the mainstream route of PERC technology development

For the traditional PERC technologies, bifacial PERC can be fully compatible with existing techniques, suitable for large-scale mass production. Based on a front-side efficiency of 22%, bifacial monocrystalline PERC can obtain significant power gain from the rear side. The rear-side power generation increases by 10%, and the comprehensive efficiency of the bifacial PERC exceeds 24%. In early 2017, mainstream enterprises, led by LONGi, released bifacial double-glass PERC modules, making bifacial a standard configuration of PERC modules.

According to the test results of bifacial module’s power generation gain under various ground conditions, bifacial module can increase the energy yield by 5%~30% depending on the application environment, bifacial double-glass PERC has significant advantage in power generation, and has high cost performance.

Half-cut-cell further improves module performance

At present, half-cut-cell has become a highlight in the development of PV module technology. According to the market analysis of ITRPV, half-cut-cell will continue to grow in the next few years, from about 5% in 2018 to about 40% in 2028, with an annual average growth rate of about 10%.

The half-cut-cell is obtained by cutting a standard cell in half and then being packaged. As a result, the internal current is reduced by half. With less current, the power loss in the cell is reduced, leading to a bigger fill factor and higher conversion efficiency. The power of the module is increased by 2~2.5%, while the unit cost of the module is basically unchanged. Compared with standard modules, the half-cut-cell module improves the electrical performance of the cell under shady or dawn/night conditions; in addition, it has a lower hot spot effect, which greatly reduces the risk of hot spot produced by the module.

Bifacial+half-cut-cell delivers remarkable cost performance

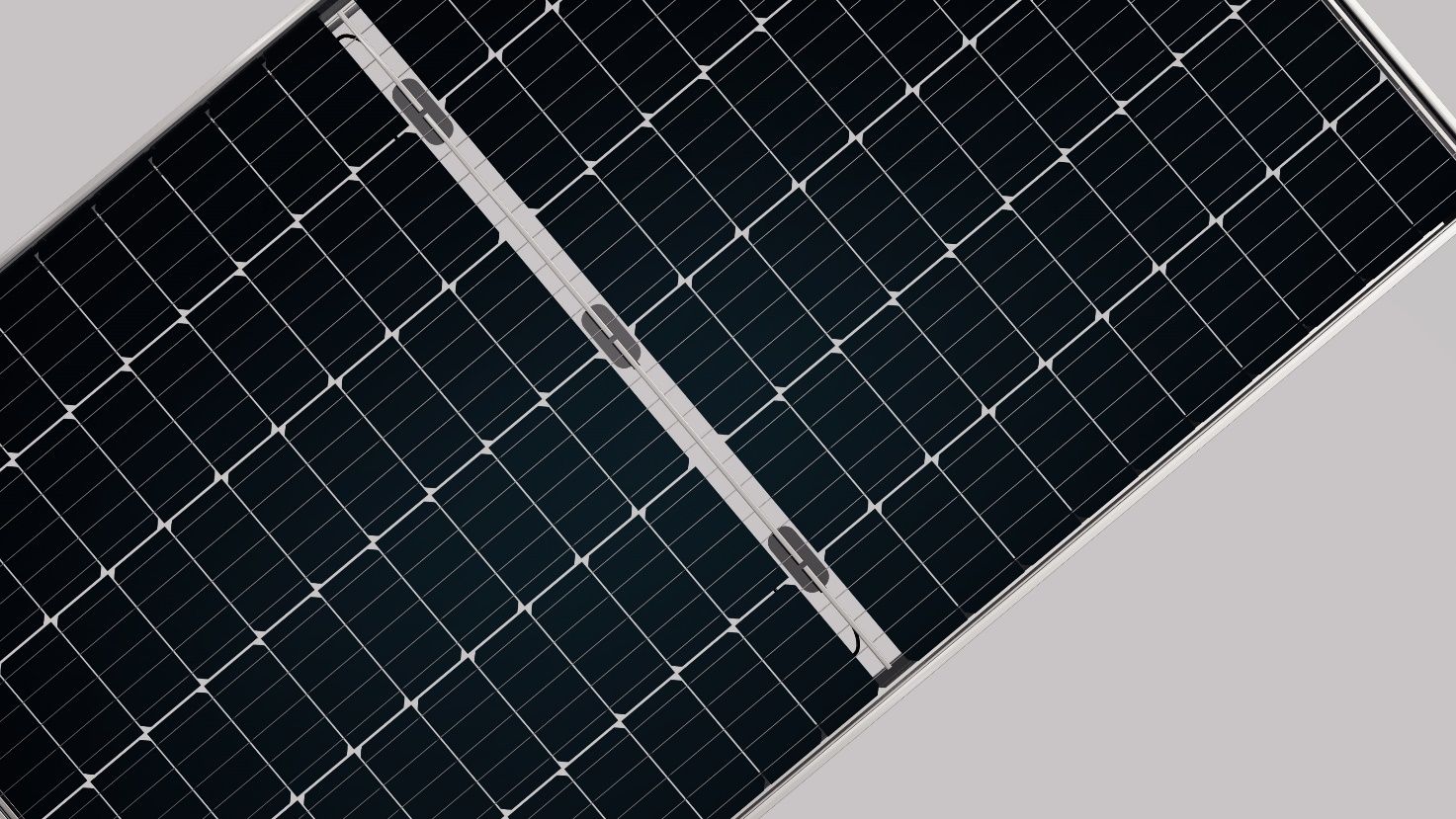

It is worth mentioning that, on the basis of bifacial, LONGi’s Hi-MO3 bifacial+half-cut-cell PERC module increases the front-side power to 320W, which has attracted wide attention in the industry. The bifacial+half-cut-cell has further highlighted the cost advantage of PERC. It’s reported that LONGi’s 60-cell monocrystalline bifacial PERC half-cut-cell module has an average cell efficiency of 22%, first-year degradation lower than 2%, stable degradation lower than 0.55%/year, and combined with bifacial technology, the front-side power of the module can reach 320W (60-cell), and the bifaciality exceeds 75%.

With respect to the power generation performance, Hi-MO3 has the high power of monocrystalline PERC. With half-cut-cell and bifacial double-glass packaging technologies, it has a better performance in such aspects as anti-shading, increasing energy yield, reducing hot spot temperature and LCOE. In high-irradiation regions or under shady conditions, Hi-MO3 will give full play to its advantages to help reduce LCOE quickly and accelerate the advent of PV grid parity in China.

LONGi Solar will attend PV-EXPO Tokyo on February 27th, 2019, bringing better LCOE solutions to customers and partners in Japan and worldwide. Please be sure to meet us at booth#E2 10-52.