It is generally recognized that half-cell technology reduces the working current of a cell string, thereby also reducing the internal loss of a PV module and improving the module’s power by more than one gear. Compared with a full cell module, half-cell technology reduces the hotspot and working temperatures of the module, significantly improving power generation performance and reliability and offering better power generation performance under shadow or uneven irradiation conditions.

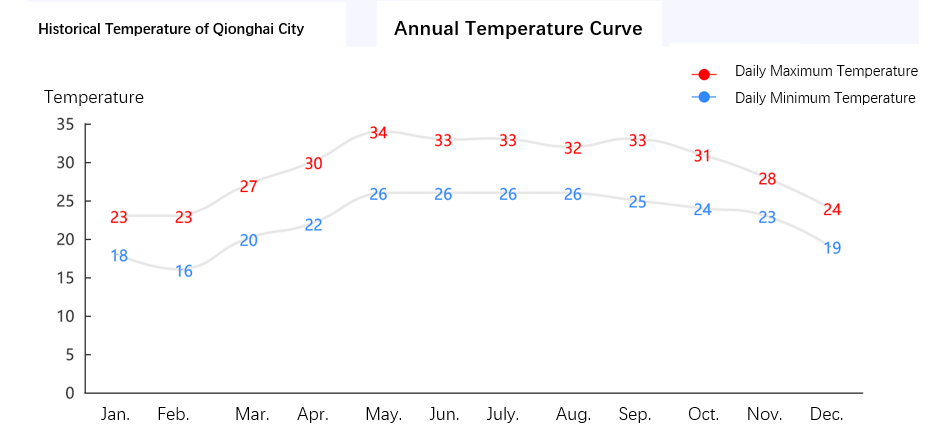

The analysis of the impact of half-cell technology on the power generation of modules is mainly seen in the early research papers of the Fraunhofer Institute and ISC, but rarely in the power generation analysis of commercial modules. In order to better study the impact of half-cell technology on module power generation, LONGi and the China Electrical Research Institute (hereinafter referred to as "CEI") jointly conducted a one-year empirical study in Qionghai, Hainan.

The demonstration power station was officially put into operation in June 2019. This article will analyze the power generation data for more than half a year.

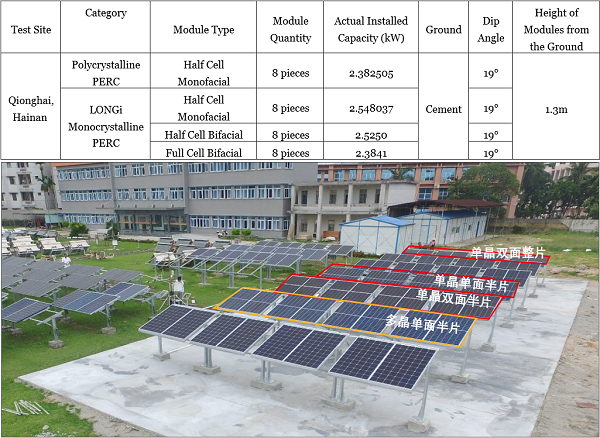

1. Test Plan

The demonstration power station is equipped with monocrystalline and bifacial full-cell modules, monocrystalline and bifacial half-cell modules and purchased polycrystalline half-cell modules (PERC technology is adopted). All modules are retested by the CEI in order to use the actual power for single Wp power generation calculation. The details are as follows:

2. Power Generation Advantages of Monocrystalline PERC over Polycrystalline PERC and Power Generation Gains of Bifacial Modules

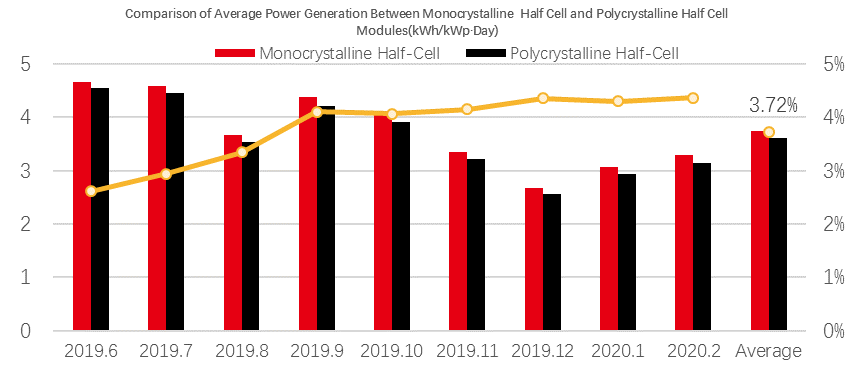

First of all, the power generation difference between monocrystalline and polycrystalline (PERC Monofacial) half-cell modules: in the 9-month statistical period, the power generation gain of a monocrystalline half-cell module is about 3.72%, which shows that the monocrystalline module maintains the advantages of low irradiance performance and power temperature coefficient when compared with a polycrystalline module. The power generation gain increases month on month. On the one hand, the advantage of winter irradiation is more obvious than that of low and weak light. On the other hand, it should be related to the excellent anti-LID performance of the LONGi module.

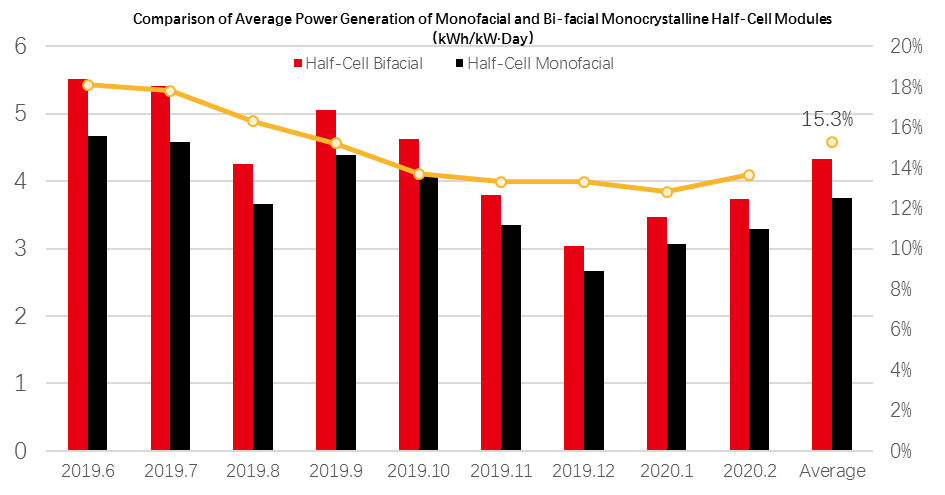

As shown in the figure above, the power generation gain of a monocrystalline half-cell bifacial module under cement surface conditions is 15.3%, compared with that of a monocrystalline half-cell module over a period of 9 months, with the gain meeting expectations.

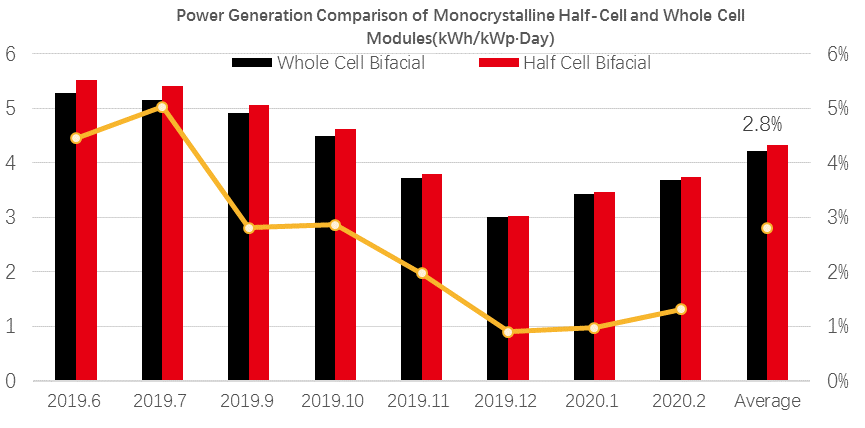

3. Analysis of the Influence of Half-Cell Technology on Power Generation of a Bifacial Module

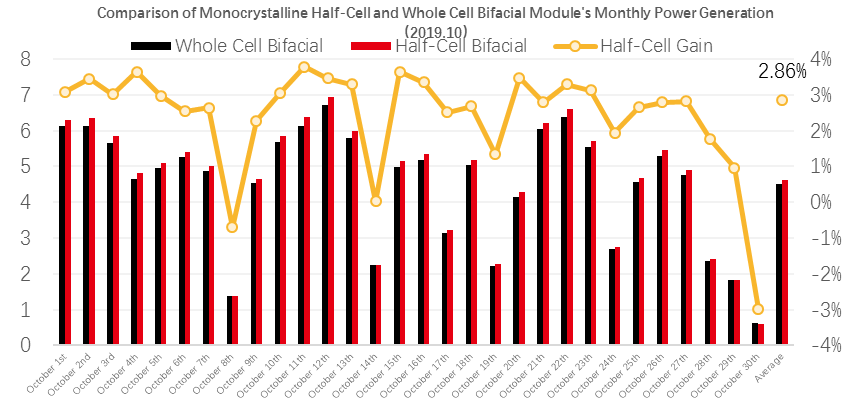

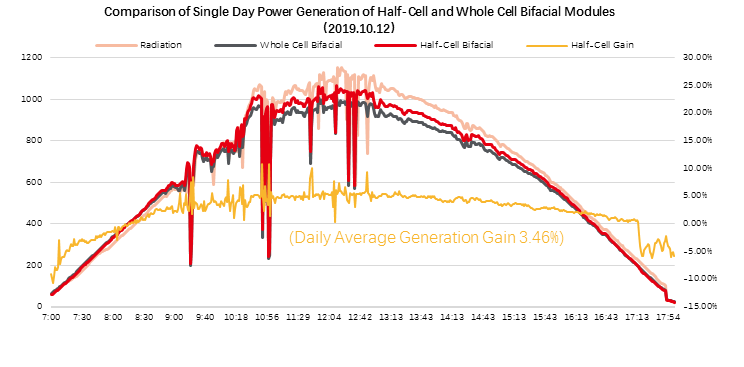

It can be seen from the statistics of a single month (October 2019) that the power generation of the half-cell bifacial module is weaker than that of the full-cell module due to irradiation differences on October 8 and 31, but power generation gains on all other days are positive, gains being generally positive related to the daily power generation.

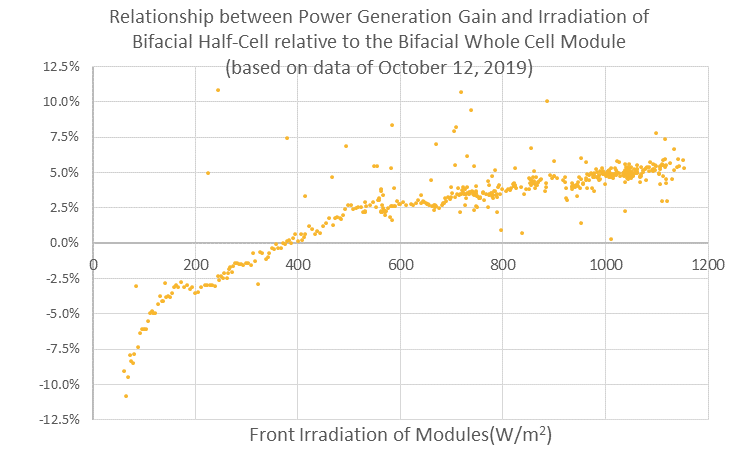

The empirical data for the Qionghai half-cell module from the CEI once again confirms the power generation gain of the LONGi monocrystalline module relative to the polycrystalline module and the bifacial gain brought by the bifacial half-cell module. Compared with the bifacial full cell module, the half-cell equivalent has an obvious power generation advantage in a high irradiation environment, and it is clear that the critical irradiation value is about 400W / m2. The high current of the monocrystalline PERC cell and the working current gain brought by the light on the rear side of the bifacial cell make bifacial PERC technology very suitable for combination with half-cell technology, which brings multiple improvements in power capacity, power generation and reliability.